A biofertilizer (also bio-fertilizer) is a substance which contains living microorganisms which, when applied to seeds, plant surfaces, or soil, colonize the rhizosphere or the interior of the plant and promotes growth by increasing the supply or availability of primary nutrients to the host plant.[1] Biofertilizers add nutrients through the natural processes of nitrogen fixation, solubilizing phosphorus, and stimulating plant growth through the synthesis of growth-promoting substances. Biofertilizers can be expected to reduce the use of synthetic fertilizers and pesticides. The microorganisms in biofertilizers restore the soil's natural nutrient cycle and build soil organic matter. Through the use of biofertilizers, healthy plants can be grown, while enhancing the sustainability and the health of the soil. Since they play several roles, a preferred scientific term for such beneficial bacteria is "plant-growth promoting rhizobacteria" (PGPR). Therefore, they are extremely advantageous in enriching soil fertility and fulfilling plant nutrient requirements by supplying the organic nutrients through microorganism and their byproducts. Hence, biofertilizers do not contain any chemicals which are harmful to the living soil.

Biofertilizers provide "eco-friendly" organic agro-input. Biofertilizers such as Rhizobium, Azotobacter, Azospirilium and blue green algae(BGA) have been in use a long time. Rhizobium inoculant is used for leguminous crops. Azotobacter can be used with crops like wheat, maize, mustard, cotton, potato and other vegetable crops. Azospirillum inoculations are recommended mainly for sorghum, millets, maize, sugarcane and wheat. Blue green algae belonging to a general cyanobacteria genus, Nostoc or Anabaena or Tolypothrix or Aulosira, fix atmospheric nitrogen and are used as inoculations for paddy crop grown both under upland and low-land conditions. Anabaena in association with water fern Azolla contributes nitrogen up to 60 kg/ha/season and also enriches soils with organic matter.[2][3]

Other types of bacteria, so-called phosphate-solubilizing bacteria, such as Pantoea agglomerans strain P5 or Pseudomonas putida strain P13,[4] are able to solubilize the insoluble phosphate from organic and inorganic phosphate sources.[5] In fact, due to immobilization of phosphate by mineral ions such as Fe, Al and Ca or organic acids, the rate of available phosphate (Pi) in soil is well below plant needs. In addition, chemical Pi fertilizers are also immobilized in the soil, immediately, so that less than 20 percent of added fertilizer is absorbed by plants. Therefore, reduction in Pi resources, on one hand, and environmental pollutions resulting from both production and applications of chemical Pi fertilizer, on the other hand, have already demanded the use of phosphate-solubilizing bacteria or phosphate biofertilizers.[citation needed]

Benefits[edit]

Benefits of biofertilizers are:[citation needed]

- These are means of fixing the nutrient availability in the soil.

- Since a bio-fertilizer is technically living, it can symbiotically associate with plant roots. Involved microorganisms could readily and safely convert complex organic material into simple compounds, so that they are easily taken up by the plants. Microorganism function is in long duration, causing improvement of the soil fertility. It maintains the natural habitat of the soil. It increases crop yield by 20-30%, replaces chemical nitrogen and phosphorus by 30%, and stimulates plant growth. It can also provide protection against drought and some soil-borne diseases.

Some important groups of biofertilizers include:[citation needed]

- Azolla-Anabena symbiosis: Azolla is a small, eukaryotic, aquatic fern having global distribution.Prokaryotic blue green algae Anabena azolla resides in its leaves as a symbiont. Azolla is an alternative nitrogen source. This association has gained wide interest because of its potential use as an alternative to chemical fertilizers.

- Rhizobium: Symbiotic nitrogen fixation by Rhizobium with legumes contribute substantially to total nitrogen fixation. Rhizobium inoculation is a well-known agronomic practice to ensure adequate nitrogen

Types of biofertilizers

Biofertilizers add nutrients through the natural processes of fixing atmospheric nitrogen, solubilizing phosphorus, and stimulating plant growth through the synthesis of growth-promoting substances. They can be categorised in different ways based on their nature and function.

One simple broadly disseminated classification is as follows:

Nitrogen Biofertilizers

This group fixes nitrogen symbiotically. Nitrogen biofertilizers help to correct the nitrogen levels in the soil. Nitrogen is a limiting factor for plant growth because plants need a certain amount of nitrogen in the soil to thrive. Different biofertilizers have an optimum effect for different soils, so the choice of nitrogen biofertilizer to be used depends on the cultivated crop. Rhizobia are used for legume crops, Azotobacter or Azospirillum for non-legume crops, Acetobacter for sugarcane and blue-green algae and Azolla for lowland rice paddies.

Phosphorus Biofertilizers

Just like nitrogen, phosphorus is also a limiting factor for plant growth. Phosphorus biofertilizers help the soil to reach its optimum level of phosphorus and correct the phosphorus levels in the soil. Unlike nitrogen biofertilizers, the usage of phosphorus biofertilizers is not dependent on the crops cultivated on the soil. Phosphatika is used for all crops with Rhizobium, Azotobacter, Azospirillum and Acetobacter.

Compost Biofertilizers

Biofertilizers are also used for enrichment of your compost and for enhancement of the bacterial processes that break down the compost waste. Suitable biofertilizers for compost use are cellulolytic fungal cultures and Phosphotika and Azotobacter cultures. A 100% pure eco-friendly organic fertilizer is Vermi Compost: this organic fertilizer has nitrogen, phosphorus, potassium, organic carbon, sulphur, hormones, vitamins, enzymes and antibiotics, which helps to improve the quality and quantity of yield. It is observed that, due to continuous misuse of chemical fertilizers, the soil looses its fertility and becomes saline day by day. To overcome such problems, natural farming is the only remedy and Vermi compost is the best solution.

Another eco-friendly organic fertilizer which is prepared from sugar industry waste material that is decomposed and enriched with various plants and human-friendly bacteria and fungi is Biocompost. Biocompost consists of nitrogen, phosphate-solubilizing bacteria and various beneficial fungi like the decomposing fungus Trichoderma viridae, which protects plants from various soil-borne diseases and also helps to increase the soil fertility, resulting in a good quality product for farmers.

A more detailed classification of biofertilizers is as follows:

Just to remind, biofertilizers are defined as biologically active products or microbial inoculants of bacteria, algae and fungi (separately or in combination), which may facilitate the biological nitrogen fixation for the benefit of plants. Biofertilizers also include organic fertilizers (manure, etc.), which are rendered in an available form due to the interaction of microorganisms or due to their association with plants.

Biofertilizers thus include the following:

- symbiotic nitrogen fixers, Rhizobium spp.;

- non-symbiotic, free-living nitrogen fixers (Azotobacter, Azospirillum, etc.);

- algal biofertilizers (blue-green algae or blue-green algae in association with Azolla);

- phosphate-solubilising bacteria;

- mycorrhizae;

- organic fertilizers.

The various biofertilizers are as follows:

- Nitrogen-fixing biofertilizers Nitrogen-fixing bacteria function under two types of conditions, symbiotically and as free-living (non-symbiotic) as well as associative symbiotic bacteria.

Free-Living Nitrogen-Fixing Bacteria:

They live freely in the soil and perform nitrogen fixation. Some of them are saprotrophic, living on organic remains, e.g., Azotobacter, Bacillus polymyxa, Clostridium, Beijerinckia. They are further distinguished into aerobic and anaerobic forms.

The property of nitrogen fixation is also found in photoautotrophic bacteria, e.g., Rhizobium, Rhodopseudomonas, Rhodospirillum, Chromatium. Inoculation of soil with these bacteria helps in increasing the yield and cutting down on nitrogen fertilizers. For example, Azotobacter occurring in fields of cotton, maize, jowar and rice not only increases the yield, but also cuts down on nitrogen fertilizer to about 10–25 kg/ha. Its inoculant is available under the trade name of Azotobactrin.

Rhizobia are soil bacteria which are able to colonize the legume roots and fix the atmospheric nitrogen symbiotically. The morphology and physiology of rhizobia will vary from free-living conditions to the bacteroid of nodules. They are the most efficient biofertilizer as per the quantity of fixed nitrogen. There are seven genera that are highly specific in forming nodules in legumes, referred to as a cross-inoculation group.

Azotobacter is a genus of heterotrophic free-living nitrogen-fixing bacteria present in alkaline and neutral soils. It is aerobic in nature, recommended for non-leguminous crops like paddy, millets, cotton, tomato, cabbage and other monocotyledonous crops. Azotobacter also produces growth-promoting compounds. Azotobacter performs well if the soil organic matter content is high. Response to Azotobacter has been seen in rice, maize, cotton, sugarcane, pearl millet, vegetable and some plantation crops.

Free-Living Nitrogen-Fixing Cyanobacteria:

A number of free-living cyanobacteria, or blue-green algae, have the property of nitrogen fixation, e.g., Anabaena, Nostoc, Aulosira, Totypothrix, Cylindrospermum, Stigonema. Cyanobacteria are photosynthetic microorganisms. Therefore, they add organic matter as well as extra nitrogen to the soil. These chlorophyll-containing prokaryotic organisms fix atmospheric nitrogen.

Aulosira fertilissima is considered to be the most active nitrogen fixer of rice fields. Cylindrospermum licheniformegrows in sugarcane and maize fields. Cyanobacteria are extremely low-cost biofertilisers. Phosphate, molybdenum and potassium are supplied additionally.

Loose Association of Nitrogen-Fixing Bacteria:

This bacterial group live partly within the root and partly outside. There is a fair degree of symbiosis between the host and the bacteria. Hence, they are called associative symbiotic bacteria. Azospirillum is an important bacterium in this group, recommended for millets, grass, wheat, maize, sorghum, rice etc.

Symbiotic Nitrogen-Fixing Bacteria:

They form a mutually beneficial association with the plants. The bacteria obtain food and shelter from plants. In return, they give to the plants part of their fixed nitrogen. The most important group of symbiotic nitrogen-fixing bacteria are rhizobia (Sg. rhizobium). They form nodules on the roots of legume plants. There are about a dozen Rhizobium species which form associations with the roots of different legumes, e.g. R. leguminosarum, R. lupini, R. trifolii, R. meliloti, R. phaseoli.

These bacteria, also called rhizobia, can live freely in the soil but cannot fix nitrogen except for a strain of cowpea Rhizobium. They develop the ability to fix nitrogen only when they are present inside the root nodules. In the nodule cells, bacteria (bacteroids) lie in groups surrounded by the membrane of the host cells, which is lined by a pink-red pigment called leghemoglobin. Presently cultures of Rhizobium specific for different crops are raised in the laboratory.

Frankia, a nitrogen-fixing mycelial bacterium (actinomycete), is associated symbiotically with the root nodules of several non-legume plants like Casuarina, Alnus (Alder) Myrica, Rubus etc. The leaves of a few plants (e.g., Ardisia) develop special internal cavities for providing space to symbiotic nitrogen-fixing bacteria, Xanthomonas and Mycobacterium. Such leaves are a constant source of nitrogen fertilizer to the soil.

Symbiotic Nitrogen-Fixing Cyanobacteria:

Nitrogen-fixing cyanobacteria (blue-green algae) form symbiotic associations with several plants, e.g. cycad roots, liverworts, Azolla (fern), and lichenized fungi. Azolla is an aquatic floating fern, found in temperate climate suitable for paddy cultivation. The fern appears as a green mat over water, which becomes reddish due to excess anthocyanin pigmentation. The blue-green algae, cyanobacteria (Anabaena azollae), present as a symbiont with this fern in the lower cavities actually fixes atmospheric nitrogen.

Azolla pinnata is a small free-floating fresh water fern which multiplies rapidly, doubling every 5–7 days. The fern can coexist with rice plants because it does not interfere with their growth.

Anabaena azollae resides in the leaf cavities of the fern. It fixes nitrogen. A part of the fixed nitrogen is excreted in the cavities and becomes available to the fern. The decaying fern plants release this nitrogen for utilization by the rice plants. When a field is dried up at the time of harvesting, the fern functions as green manure, decomposing and enriching the field for the next crop.

Microphos Biofertilizers:

They release phosphate from bound and insoluble states, e.g., Bacillus polymyxa, Pseudomonas striata, Aspergillusspecies.

Mycorrhiza (Pl. Mycorrhizae, Frank, 1885):

The mycorrhiza is a mutually beneficial or symbiotic association of a fungus with the root of a higher plant. The most common fungal partners of mycorrhiza are Glomus species. Mycorrhizal roots show a sparse or dense wooly growth of fungal hyphae on their surface. Root cap and root hairs are absent.

Mycorrhiza is a potential biofertilizer which mobilizes P, Fe, Zn, B and other trace elements. It supplies moisture from far-off inches and is ideal for long duration crops. It can be stored up to 2 years and is dry powder resistant.

Depending upon the residence of the fungus, mycorrhizae are of two types— ectomycorrhiza and endomycorrhiza.

Ectomycorrhiza (= Ectotrophic Mycorrhiza):

The fungus forms a mantle on the surface of the root. Internally, it lies in the intercellular spaces of the cortex. The root cells secrete sugars and other food ingredients into the intercellular spaces that feed the fungal hyphae. The exposed fungal hyphae increase the surface of the root to several times. They perform several functions for the plant as follows:

- Absorption of water,

- Solubilisation of organic matter of the soil humus, release of inorganic nutrients, absorption and their transfer to root,

- Direct absorption of minerals from the soil over a large area and handing over the same to the root. Plants with ectomycorrhiza are known to absorb 2–3 times more of nitrogen, phosphorus, potassium and calcium,

- The fungus secretes antimicrobial substances which protect the young roots from attack of pathogens. Ectomycorrhiza occurs in trees such as Eucalyptus, oak (Quercus), peach, pine, etc. The fungus partner is generally specific. It belongs to Basidiomycetes.

Endomycorrhiza (Endotrophic Mycorrhiza):

Fewer fungal hyphae lie on the surface. The remaining live in the cortex of the root, mostly in the intercellular spaces with some hyphal tips passing inside the cortical cells, e.g., grasses, crop plants, orchids and some woody plants. At the seedling stage of orchids, the fungal hyphae also provide nourishment by forming nutrient-rich cells called pelotons. Intracellular growth occurs in order to obtain nourishment because, unlike ectomycorrhiza, the cortical cells do not secrete sugars in the intercellular spaces.

Vesicular Arbuscular Mycorrhizal (VAM) fungi possess special structures known as vesicles and arbusculars. VAM fungi are intercellular, obligate endosymbionts and, on establishment on the root system, act as an extended root system. Besides harvesting moisture from deeper and faraway nitches in the soil, they also harvest various micronutrients and provide them to the host plants. VAM facilitates the phosphorus nutrition by not only increasing its availability, but also increasing its mobility. VAM are obligate symbionts and improve the uptake of Zn, Co, P and H2O. Its large-scale application is limited to perennial crops and transplanted crops. A single fungus may form a mycorrhizal association with a number of plants, e.g., Glomus.

The different types of biofertilizers are preparations made from natural beneficial microorganisms. They are safe for all plants, animals and human beings. Being beneficial to crops and natural nutrient cycles, they not only are environmentally friendly, but also help in saving of chemical inputs.

Main roles of biofertilizers:

- Make nutrients available.

- Make the root rhizosphere livelier.

- Growth-promoting substances are produced.

- More root proliferation.

- Better germination.

- Improve the quality and quantity of produce.

- Improve the fertilizer use efficiency.

- Higher biotic and abiotic stress tolerance.

- Improve soil health.

- Residual effect.

- Make the system more sustainable.

Liquid Biofertilizers

At present, biofertilizers are supplied to the farmers as carrier-based inoculants. As an alternative, liquid formulation technology has been developed which has more advantages than the carrier inoculants.

Benefits:

The advantages of liquid biofertilizer over conventional carrier-based biofertilizers are listed below:

- Longer shelf-life – 12–24 months;

- No contamination;

- No loss of properties due to storage up to 45º C;

- Greater potential to fight with native population;

- Easy identification by typical fermented smell;

- Better survival on seeds and soil;

- Very easy to use by the farmer;

- High commercial revenues;

- High export potential.

Characteristics of different liquid biofertilizers

Rhizobium

Physical features of liquid Rhizobium biofertilizer:

- Dull white in colour;

- No bad smell;

- No foam formation, pH 6.8–7.5

Azospirillum

Physical features of liquid Azospirillum biofertilizer:

- The colour of the liquid may be blue or dull white.

- Bad odour confirms improper liquid formulation and may be considered as mere broth.

- Production of yellow gummy colour materials confirms the quality product.

- Acidic pH always confirms that there are no Azospirillum bacteria in the liquid.

Role of liquid Azospirillum under field conditions:

- Stimulates growth and imparts green colour which is a characteristic of a healthy plant.

- Aids utilization of potash, phosphorous and other nutrients.

- Enhances the plumpness and succulence of fruits and increases the protein content.

Azotobacter

Physical features of liquid Azotobacter biofertilizer:

The pigment that is produced by Azotobacter in aged culture is melanin, which is due to oxidation of tyrosine by a copper-containing enzyme, tyrosinase. The colour can be seen in liquid forms. Some of the pigmentations are described below:

- Produces brown-black pigmentation in liquid inoculum;

- Produces yellow-light brown pigmentation in liquid inoculum;

- Produces green fluorescent pigmentation in liquid inoculum;

- Produces green fluorescent pigmentation in liquid inoculum;

- Produces, pink pigmentation in liquid inoculum;

- Produces less, gum-less, greyish-blue pigmentation in liquid inoculum;

- Produces green-fluorescent pigmentation in liquid inoculum.Acetobacter

These are sacharophillic bacteria associated with sugarcane, sweet potato and sweet sorghum plants. Acetobacterfixes 30 kg N/ha/year. This bacterium is mainly commercialized for sugarcane crops. It is known to increase the yield by 10–20 t/acre and sugar content by about 10–15 percent.

Advantages of the production technology of biofertilizers

| Carrier-based | Liquid-based |

|---|---|

| Cheap | Longer shelf-life |

| Easier to produce | Easier to produce |

| Less investment | Temperature tolerant |

| High cell counts | |

| Contamination-free | |

| More effective | |

| Product can be 100% sterile | |

| Disadvantages | |

| Low shelf-life | High cost |

| Temperature sensitive | Higher investment for production unit |

| Contamination prone | |

| Low cell counts | |

| Less effective | |

| Automation difficult |

There are five biofertilizers viz. Rhizobium, Azotobacter, Azospirillum, Phosphate Solubilizing Bacteria and mycorrhiza , which have been incorporated

A biofertilizer is not just any organic fertilizer or manure. It consists of a carrier medium rich in live microorganisms. When applied to seed, soil or living plants, it increases soil nutrients or makes them biologically available. Biofertilizers contain different types of fungi, root bacteria or other microorganisms. They form a mutually beneficial or symbiotic relationship with host plants as they grow in the soil. Biofertilizers have many advantages and a few disadvantages.

VIDEO OF THE DAY

Sustainability

Biofertilizers increase the nitrogen and phosphorus available to plants more naturally than other fertilizers.The different varieties available allow growers to tailor the microorganisms used to the needs of particular plants. Biofertilizers are simple to use, even for novice small growers. Biofertilizers do not pollute the soil or the environment, whereas chemical fertilizers often result in too much phosphate and nitrogen in the soil. The excess then leaches into lakes and streams through runoff. Waters decline in quality and suffer from overgrowth of algae and the death of fish.

Affordability

Biofertilizers reduce dependence upon expensive petroleum sources of chemical fertilizers. According to the "Journal of Phytology," demand for chemical fertilizers will exceed the supply by more than 7 million tons by 2020. The shortage of fossil fuels to produce chemical fertilizers may drive up prices beyond the reach of small users. Biofertilizers are a cheap, easy-to-use alternative to manufactured petrochemical products.

Improved Soil

Biofertilizers restore normal fertility to the soil and make it biologically alive. They boost the amount of organic matter and improve soil texture and structure. The enhanced soil holds water better than before. Biofertilizers add valuable nutrients to the soil, especially nitrogen, proteins and vitamins. They take nitrogen from the atmosphere and phosphates from the soil and turn them into forms that plants can use. Some species also produce natural pesticides.

Improved Plants

Biofertilizers increase yield by up to 30 percent because of the nitrogen and phosphorus they add to the soil. The improvement in soil texture and quality helps plants grow better during periods of drought. Biofertilizers help plants develop stronger root systems and grow better. Biofertilizers also reduce the effects of harmful organisms in the soil, such as fungi and nematodes. Plants resist stress better and live longer.

Disadvantages

Biofertilizers require special care for long-term storage because they are alive. They must be used before their expiration date. If other microorganisms contaminate the carrier medium or if growers use the wrong strain, they are not as effective. The soil must contain adequate nutrients for biofertilizer organisms to thrive and work. Biofertilizers complement other fertilizers, but they cannot totally replace them. Biofertilizers lose their effectiveness if the soil is too hot or dry. Excessively acidic or alkaline soils also hamper successful growth of the beneficial microorganisms; moreover, they are less effective if the soil contains an excess of their natural microbiological enemies. Shortages of particular strains of microorganisms or of the best growing medium reduce the availability of some biofertilizers.

Biofertilizers are the substance that contains microorganism’s living or latent cells. Biofertilizers increase the nutrients of host plants when applied to their seeds, plant surface or soil by colonizing the rhizosphere of the plant. Biofertilizers are more cost-effective as compared to chemical fertilizers.

Over the years, chemical fertilizers have helped farmers increase crop production to meet the increasing demand. However, the overuse of these fertilizers is harmful because they cause air and water pollution; and also deplete minerals from the soil. Therefore, there is a need to now switch to organic farming which involves the use of ‘Biofertilizers’. Let’s learn more about biofertilizers and some of their types.

Biofertilizers

‘Bio’ means ‘life’. Therefore, by definition biofertilizers are living organisms that enrich the nutrient quality of the soil. It refers to the use of microbes instead of chemicals to enhance the nutrition of the soil. As a result, it is also less harmful and does not cause pollution.

This is what makes them so important to organic farming because they are completely environment-friendly. Let’s take a look at the different microbes that are used as biofertilizers.

Types of Biofertilizers:

- Bacteria

- Fungi

- Cyanobacteria

Bacteria

You may have already studied the nitrogen-fixing nodules on the roots of legumes. This a great example of biofertilizers. The nodules are formed by the association of the bacterium ‘Rhizobium’ with the roots of these plants. This association is beneficial and is, therefore, called ‘symbiotic’.

The nodules help in fixing atmospheric nitrogen into organic forms which can then be used as nutrition by the plants. Adding Rhizobium cultures to fields has become a common practice to ensure an adequate amount of nitrogen in the soil.

Other examples of bacteria that act as biofertilizers include Azospirillum and Azotobacter. These bacteria are free-living in the soil. Azotobacter is usually used with crops like cotton, wheat, mustard, maize, etc.

Fungi

Symbiotic associations exist between plants and fungi too. These associations are called ‘Mycorrhizae’. The fungus in this association absorbs phosphorus from the soil and provides it to the plant. Plants that grow with these associations also show other advantageous characteristics such as:

- Tolerance to drought conditions and salinity.

- Resistance to root-borne pathogens.

- An overall increase in plant growth and development.

Cyanobacteria

These are blue-green bacteria found in water and on land. They also help fix atmospheric nitrogen. Examples are Oscillatoria, Nostoc, Anabaena etc. The symbiotic association between the aquatic fern Azolla and Anabaena is very important for rice fields. In this association, Anabaena receives carbon and nitrogen from the plant in exchange for fixed nitrogen. This adds organic matter to the soil enhancing the fertility of rice fields.

Nowadays, many biofertilizers are commercially available in the market for farmers to buy and use. These not only help replenish the soil nutrients but also reduce the dependency on chemical fertilizers. This helps in maintaining the mineral content of the soil and reduces pollution to a great extent.

Solved Example For You

Question: Which of these biofertilizers provide phosphorus to the plants?

- Oscillatoria

- Rhizobium

- Nostoc

- Mycorrhizae

Solution: The correct answer is option “d”. Mycorrhizae provides phosphorus to the plants while the others fix atmospheric nitrogen that can be used by the plants.

Biofertilizer Mycorrhiza as Biofertilizers

Mycorrhiza (fungus roots) is a distinct morphological structure which develops as a result of mutualistic symbiosis between some specific root - inhabiting fungi and plant roots. Plants which suffer from nutrient scarcity, especially P and N, develop mycorrhiza i.e. the plants belong to all groups e.g. herbs, shrubs, trees, aquatic, xerophytes, epiphytes, hydrophytes or terrestrial ones. In most of the cases plant seedling fails to grow if the soil does not contain inoculum of mycorrhizal fungi.

In recent years, use of artificially produced inoculum of mycorrhizal fungi has increased its significance due to its multifarous role in plant growth and yield, and resistance against climatic and edaphic stresses, pathogens and pests.

Mechanism of Symbiosis

The mechanism of symbiosis is not fully understood. Biorkman (1949) postulated the carbohydrate theory and explained the development of mycorrhizas in soils deficient in available P and N, and high light intensity. Slankis (1961) found that at high light intensity, surplus carbohydrates are formed which are exuded from roots. This in turn induces the mycorrhizal fungi of soil to infect the roots. At low light intensity, carbohydrates are not produced in surplus, therefore, plant roots fail to develop mycorrhizas. Types of Mycorrhizas

By earlier mycologists the mycorrhizas were divided into the following three groups :

(i) Ectomycorrhiza. It is found among gymnosperms and angiosperms. In short roots of higher plants generally root hairs are absent. Therefore, the roots are infected by mycorrhizal fungi which, in turn, replace the root hairs (if present) and form a mantle. The hyphae grow intercellularly and develop Hartig net in cortex. Thus, a bridge is established between the soil and root through the mycelia.

(ii) Endomycorrhiza. The morphology of endomycorrhizal roots, after infection and establishment, remain unchanged. Root hairs develop in a normal way. The fungi are present on root surface individually. They also penetrate the cortical cells and get established intracellulary by secreting extracellular enzymes. Endomycorrhizas are found in all groups of plant kingdom.

(iii) Ectendomycorrhiza. In the roots of some of the gymnosperms and angiosperms, ectotrophic fungal infection occur. Hyphae are established intracellularly in cortical cells. Thus, symbiotic relation develops similar to ecto- and endo-mycorrhizas.

Marks (1991) classified the mycorrhizas into seven types on the basis of types of relationships with the hosts (i) vesicular-arbuscular (VA) mycorrhizas (coiled, intracellular hyphae, vesicle and arbuscules present), (ii) ectomycprrhizas (sheath and inter-cellular hyphae present), (iii) ectendomycorrhizas (sheath optional, inter and intra-cellular hyphae present), (iv) arbutoid mycorrhizas (seath, inter-and coiled intracellular hyphae present), (v) monotropoid mycorrhizas (sheath, inter- and intra- cellular hyphae and peg like haustoria present), (vi) ericoid mycorrhizas (only coiled intracellular hyphae, long coiled hyphae present), and (viii) orchidaceous mycorrhizas (only coiled intracellujlar hyphae present). Type (i) is present in all groups of plant kingdom; Types (ii) and (iii) are found in gymnosperms and angiosperms. Types (iv), (v)and (vi) are restricted to Ericales, Monotropaceae and Ericales respectively. Types (vii)is restricted to Orchidaceous only. Types (iv) and (v) were previously grouped under ericoid mycorrhizaes.

Methods of Inoculum Production and Inoculation

Methods of inoculum production of VAM fungi differ; however, some of these two are briefly described here.

(a) Ectomycorrhizal fungi: The basidiospores, chopped sporocarp, sclerotia, pure mycelia culture, fragmented mycorrhizal roots or soil from mycorrhizosphere region can be used as inoculum. The inoculum is mixed with nursery soils and seeds are sown.

Institute for Mycorrhizal Research and Development, U.S.A., Athens and Abbort Laboratories (U.S.A) have developed a mycelial inoculum of Pisolithus tinctorius in a vermiculite-peat moss substrate with a trade name ‘Myco-Rhiz’ which is now commercially available on large quantities. In 1982, about 1.5 million pine seedlings were produced with MycoRhiz in the U.S.A. (Marx and Schenck, 1983).

(b) VA mycorrhizal fungi : VA mycorrhizas can be produced on a large scale by pot culture technique. This requires the host plants, mycorrhizal fungi and natural soil. The host plants which support large scale production of inoculum are sudan grass, strawberry, sorghum, maize, onion, citrus, etc.

In recent years, use of artificially produced inoculum of mycorrhizal fungi has increased its significance due to its multifarous role in plant growth and yield, and resistance against climatic and edaphic stresses, pathogens and pests.

Mechanism of Symbiosis

The mechanism of symbiosis is not fully understood. Biorkman (1949) postulated the carbohydrate theory and explained the development of mycorrhizas in soils deficient in available P and N, and high light intensity. Slankis (1961) found that at high light intensity, surplus carbohydrates are formed which are exuded from roots. This in turn induces the mycorrhizal fungi of soil to infect the roots. At low light intensity, carbohydrates are not produced in surplus, therefore, plant roots fail to develop mycorrhizas. Types of Mycorrhizas

By earlier mycologists the mycorrhizas were divided into the following three groups :

(i) Ectomycorrhiza. It is found among gymnosperms and angiosperms. In short roots of higher plants generally root hairs are absent. Therefore, the roots are infected by mycorrhizal fungi which, in turn, replace the root hairs (if present) and form a mantle. The hyphae grow intercellularly and develop Hartig net in cortex. Thus, a bridge is established between the soil and root through the mycelia.

(ii) Endomycorrhiza. The morphology of endomycorrhizal roots, after infection and establishment, remain unchanged. Root hairs develop in a normal way. The fungi are present on root surface individually. They also penetrate the cortical cells and get established intracellulary by secreting extracellular enzymes. Endomycorrhizas are found in all groups of plant kingdom.

(iii) Ectendomycorrhiza. In the roots of some of the gymnosperms and angiosperms, ectotrophic fungal infection occur. Hyphae are established intracellularly in cortical cells. Thus, symbiotic relation develops similar to ecto- and endo-mycorrhizas.

Marks (1991) classified the mycorrhizas into seven types on the basis of types of relationships with the hosts (i) vesicular-arbuscular (VA) mycorrhizas (coiled, intracellular hyphae, vesicle and arbuscules present), (ii) ectomycprrhizas (sheath and inter-cellular hyphae present), (iii) ectendomycorrhizas (sheath optional, inter and intra-cellular hyphae present), (iv) arbutoid mycorrhizas (seath, inter-and coiled intracellular hyphae present), (v) monotropoid mycorrhizas (sheath, inter- and intra- cellular hyphae and peg like haustoria present), (vi) ericoid mycorrhizas (only coiled intracellular hyphae, long coiled hyphae present), and (viii) orchidaceous mycorrhizas (only coiled intracellujlar hyphae present). Type (i) is present in all groups of plant kingdom; Types (ii) and (iii) are found in gymnosperms and angiosperms. Types (iv), (v)and (vi) are restricted to Ericales, Monotropaceae and Ericales respectively. Types (vii)is restricted to Orchidaceous only. Types (iv) and (v) were previously grouped under ericoid mycorrhizaes.

Methods of Inoculum Production and Inoculation

Methods of inoculum production of VAM fungi differ; however, some of these two are briefly described here.

(a) Ectomycorrhizal fungi: The basidiospores, chopped sporocarp, sclerotia, pure mycelia culture, fragmented mycorrhizal roots or soil from mycorrhizosphere region can be used as inoculum. The inoculum is mixed with nursery soils and seeds are sown.

Institute for Mycorrhizal Research and Development, U.S.A., Athens and Abbort Laboratories (U.S.A) have developed a mycelial inoculum of Pisolithus tinctorius in a vermiculite-peat moss substrate with a trade name ‘Myco-Rhiz’ which is now commercially available on large quantities. In 1982, about 1.5 million pine seedlings were produced with MycoRhiz in the U.S.A. (Marx and Schenck, 1983).

(b) VA mycorrhizal fungi : VA mycorrhizas can be produced on a large scale by pot culture technique. This requires the host plants, mycorrhizal fungi and natural soil. The host plants which support large scale production of inoculum are sudan grass, strawberry, sorghum, maize, onion, citrus, etc.

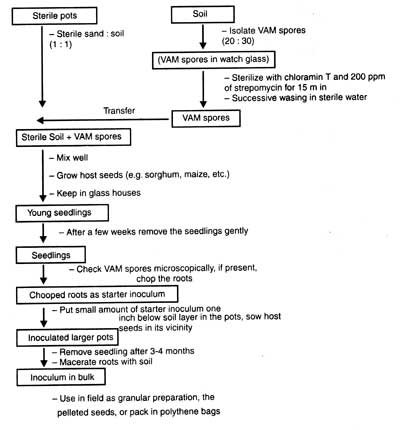

The starter inoculum (spores) of VA mycorrhizal fungi can be isolated from soil by wet sieving and decantation technique (Gerdeman and Nicolson, 1963). VA mycorrhizal spores are surface sterilized and brought to the pot culture. Commonly used pot substrates are sand: soil (1:1, w/w) with a little amount of moisture. An out line for inoculum production is given in Fig. 12.5.

There are two methods of using the inoculum : (i) using a dried spore-root- soil to plants by placing the inoculum several centimeters below the seeds or seedlings, (ii) using a mixture of soil-roots, and spores in soil pellets and spores adhered to seeds with adhesives.

Commercially available pot culture of VA mycorrhizal hosts grown under aseptic conditions can provide effective inoculum. Various types of VA mycorrhizal inocula are currently produced by Native Plants, Inc (NPI), Salt Lake City.

In India, Forest Research Institute, Dehra Dun has established mycorrhizal bank in different states of the country. Inocula of these can be procured as needed and used in horticulture and forestry programmes.

Benefits from Mycorrhizas to Plants

| i) | They increase the longevity of feeder roots, surface area of roots by forming mantle and spreading mycelia into soil and, in turn, the rate of absorption of major and minor nutrients from soil resulting in enhanced plant growth. |

| (ii) | They play a key role for selective absorption of immobile (P, Zn and Cu) and mobile (S, Ca, K, Fe, Mn, Cl, Br, and N) elements to plants. These are available to plants in less amount (Tinker, 1984). |

| (iii) | Some of the trees like pines cannot grow in new areas unless soil has mycorrhizal inocula because of limited or coarse root hairs. |

| (iv) | VA mycorrhizal fungi enhance water uptake in plants, |

| (v) | VA mycorrhizal fungi reduce plant response to soil stress such as high salt levels, toxicity associated with heavy metals, mine spoils, drought and minor element (e.g. Mn) imbalance. |

| (vi) | VA mycorrhizal fungi decrease transplant socks to seedlings. They produce organic 'glues' which bind soil particles into semistable in aggregates. Thus, they play a significant role in augmenting soil fertility and plant nutrition. |

| (vii) | Some of them produce metabolites which change the ability of plants to induce roots from woody plant cuttings and increase root development during vegetative propagation. |

| (viii) | They increase resistance in plants and with their presence reduce the effects of pathogens and pests on plant health. |

About VAM

One of our first microbiological products is Vesicular Arbuscular Mycorrhizal (VAM). VAM is a fungus that penetrates the roots of a vascular plant in order to help them to capture nutrients from the soil. These fungi are scientifically well known for their ability to uptake and transport mineral nutrients from the soil directly into host plant roots. Approximately 80% of known plant species, including most economically important crops, have a known symbiosis with them.

This mutually beneficial partnership between plants and soil fungi has existed as long as there have been plants growing in soil. Unfortunately, these beneficial mycorrhizal fungi are destroyed in the development of human-made landscapes, causing vegetation in these environments to struggle. When reintroduced to the soil (see diagram), the mycorrhiza colonizes the root system, forming a vast network of filaments. This fungal system retains moisture while producing powerful enzymes that naturally unlock mineral nutrients in the soil for natural root absorption.

(Click to enlarge)

Thanks to their incredible ability to connect to plant roots, the microscopic fungal fibres vastly extend the root system. They extract water and nutrients from a large volume of surrounding soil, and bring them to the plant, improving nutrition and growth. A plant’s root system, however big, can never be as extensive as the network of fungal fibres. The microscopic filaments grow through the soil and reach much more nutrients than the roots would. When you treat your plants with mycorrhiza, you can be sure that they will use the whole potential of the soil.

By supplying the plant with much more extra water and nutrients, mycorrhizal fungi contribute to superior growth, resistance and health. Just like people should have a good supply of water and a healthy lifestyle based on natural, organic products, so our plants grow much better when they live with a life-long partner and without chemical fertilizers. When we provide them with a solid base and the best possible support, they are much more likely to survive periods of bad conditions.

If you wanted to simply take the mycelium and put it under your plant, it wouldn’t work very well. First, we need to multiply the reproductive particles of the fungi, to make sure that they start growing new offshoots when they get to the roots of your plant. Then, we make a concentrated extract with ingredients that support the establishment of mycorrhiza, so that the customer gets maximum benefit from our products.

Where is it found?

When you see a mushroom or a toadstool, you usually only see what is above the ground. But the majority of the organism is found underground, in the form of fine fungal fibres that stretch for metres through the soil, and the above-ground mushrooms are just a small part of the whole structure. The network of underground fibres connects to plant roots and acts as an enormous additional root system.

Is there only one kind of mycorrhizal fungi?

There are several types and each works in a slightly different way. This is why in our laboratories, we first seperate and multiply the individual species, and then mix them together to suit the specific needs and demands of different customers. Different plants need different species of mycorrhizal fungi, and the specific formulation can only be reached by involving expert biologists and mycologists in the production.

Is mycorrhiza a fertilizer?

No, fertilizers are important, because they release nutrients into the soil. But only combining natural, slow-release fertilizers with mycorhizal fungi can get you the strong, resistant and healthy plants you strive for.

(Click to enlarge images)

What can we expect from mycorrhizal treatment?

Better and more balanced growth

Healthier and more dense root system with a largely improved ability to get nutrients from soil

Richer and denser flowers and fruit

Significantly lower need of watering and fertilizing

Higher resistance to drought

Decreased stress during transplanting

Stabilization of surface

Protection against some soil pathogenes and diseases

Why is all this so important?

It is a natural mutually beneficial partnership between plants and some soil fungi.

It actively fights various soil diseases and parasites.

It is capable of storing water, which further reinforces the root system.

Makes the soil resistant to erosion, strengthens the plants overall health and provides long-term, natural support for your plant.

But one of the most important abilities of mycorrhizal fungi is that they stay attached to the roots and support the plant for its entire life.

Biofertilizer

Biofertilizers are defined as preparations containing living cells or latent cells of efficient strains of microorganisms that help crop plants’ uptake of nutrients by their interactions in the rhizosphere when applied through seed or soil. They accelerate certain microbial processes in the soil which augment the extent of availability of nutrients in a form easily assimilated by plants.

Very often microorganisms are not as efficient in natural surroundings as one would expect them to be and therefore artificially multiplied cultures of efficient selected microorganisms play a vital role in accelerating the microbial processes in soil.

Use of biofertilizers is one of the important components of integrated nutrient management, as they are cost effective and renewable source of plant nutrients to supplement the chemical fertilizers for sustainable agriculture. Several microorganisms and their association with crop plants are being exploited in the production of biofertilizers. They can be grouped in different ways based on their nature and function.

| . No. | Groups | Examples |

N2 fixing Biofertilizers

| ||

| 1. | Free-living | Azotobacter, Beijerinkia, Clostridium, Klebsiella, Anabaena, Nostoc, |

| 2. | Symbiotic | Rhizobium, Frankia, Anabaena azollae |

| 3. | Associative Symbiotic | Azospirillum |

P Solubilizing Biofertilizers

| ||

| 1. | Bacteria | Bacillus megaterium var. phosphaticum, Bacillus subtilis Bacillus circulans, Pseudomonas striata |

| 2. | Fungi | Penicillium sp, Aspergillus awamori |

P Mobilizing Biofertilizers

| ||

| 1. | Arbuscular mycorrhiza | Glomus sp.,Gigaspora sp.,Acaulospora sp., Scutellospora sp. & Sclerocystis sp. |

| 2. | Ectomycorrhiza | Laccaria sp., Pisolithus sp., Boletus sp., Amanita sp. |

| 3. | Ericoid mycorrhizae | Pezizella ericae |

| 4. | Orchid mycorrhiza | Rhizoctonia solani |

Biofertilizers for Micro nutrients

| ||

1.

|

Silicate and Zinc solubilizers

|

Bacillus sp.

|

Plant Growth Promoting Rhizobacteria

| ||

1.

|

Pseudomonas

|

Pseudomonas fluorescens

|

NFL manufactures and markets three types of Bio-Fertilizers, Rhizobium, Phosphate Solubilising Bacteria (PSB) and Azetobactor. Starting with a mere 23 MT production in 1995-96, the production has risen to 231 MT (Approx) in 2010-11. The Company presently markets its bio-fertilizers in Madhya Pradesh, Maharashtra, Uttar Pradesh, Uttrakhand, Chattisgarh, Bihar, Jharkhand, Himachal Pradesh, Jammu & Kashmir, Punjab, Haryana & Rajasthan.

Bio-fertilizers are used to supplement chemical fertilizers as also to maintain soil fertility; besides the following:-

- Bio-Fertilizers are supplement to Chemical Fertilizers.

- Bio-Fertilizers are cheap and can reduce the cost of cultivation.

- Fix Biological Nitrogen in the soil, which is readily available to the plant.

- Increase crop yield by 4-5% on an average.

- Improve soil properties and sustain soil fertility.

- Provides plant nutrient at low cost and useful for the consecutive crops.

The applicability of Bio-Fertilizers marketed by NFL of different crops is as under:

| Name of Bio-Fertilizers | Contribution | Most Beneficiary Crop |

| A. NitrogenBio-Fertilizer 1.Rhizobium(Symbiotic) | a) Fixes 50-300 Kg. N/hactre b) Leaves residual nitrogen for succeeding crop. c) Increase yield by 10-35% d) Maintains soil fertility. |

Pulse Legumes : Gram, Peas, Lentil, Moong, Urd, Cowpea, Arhar. Oil

Legumes : Groundnut and Soyabeans. Fodder Legumes : Barseem, Lucerne. Forest Legumes : Subabul, Shisam, Shinsh. |

| 2. Azetobactor (Non-Symbiotic) |

a) Fixes 20-40 mgN/g of C-Source

b) Produces growth promoting substances like vitamin B groups, Indole acetic acid and Giberellic acid. c) 0-15% increase in yield. d) Maintains soil fertility. e) Biological control of plant diseases by suppressing some plant pathogens. |

Wheat, Jowar, Barley, Maize, Paddy, Mustard, Sunflower, Sesamum. Cotton, Sugarcane, Banana, Grapes, Papaya,Watermelon, Onion, Potato, Tomato, Cauliflower, Chilly, Lady finger, Rapeseed, Linseed, Tobacco. Mulberry, Coconut, Spices, Fruits, Flowers. Plantation crops, Forest plants

|

B) Phosphorous

Bio-fertilizer 1. P.S.B. Phosphate solubilising Bacteria |

a) Solublizes insoluble

phosphate. b) Increases yield by 10-30%. c) Produce enzymes which mineralise organic phosphorous to a solubleform. |

Non-specific : All Plants.

|

What is the difference between Organic fertilizer and Bio-fertilizers?

Answer by Judies Frady:

Bio-organic fertilizer, which is finished organic fertilizer, is purified by means of physical methods to reduce the moisture of manure. Today, so many organic fertilizer plants are also can produce bio organic fertilizer with same fertilizer production line. Bio-organic fertilizer is the fertilizer with the function of both microbial fertilizer and organic fertilizer. with animal and plant residues (such as manure, straw, etc.) as the raw materials and special funtional microbes, by sound processing and decomposition, finished appearance (sensory) for the product should be loose powder, no bad smell; particulate product should be no mechanical impurities, uniform size, taste-free.Require the use of microbial strains should be safe, effective, and there is a clear source of Species.The difference between the two:First, the presence or absence of microorganisms. Bio-organic fertilizer contains a variety of beneficial microorganisms inside, but all microorganisms in organic fertilizer after high temperature treatment substantially are killed, which is difficult to provide beneficial soil microbes.Second, different nutrients. Organic fertilizer through high-temperature treatment, nutrient losses during treatment of high temperature.Third, different odors. Organic fertilizer by drying, deodorizing effect of organic fertilizer is not ideal because of drying treatment. once organic fertilizer is damp, stench is issued. Bio-organic fertilizer fundamentally eliminate the odor, because it can turn uric acid into the urine bacterial protein.Item Index of organic fertilizer technical indicatorsOrganic matter content (dry basis), ≥45%Total nutrient (N + P2O5 + K2O) content (dry basis), ≥5.0%Moisture (free water) content, ≤30%PH pH 5.5-8.0Heavy metal content, Ascaris eggs and E. coli mortality value indicators in organic fertilizer should be normal by governmental requirements.Technical requirements for bio-organic fertilizerItem IndexThe effective number of viable cells (cfu), ≥ 0.20 g/ one hundred millionOrganic matter (dry basis), ≥ 40.0%Moisture, ≤ 30.0%pH value of 5.5 to 8.5Fecal coliform, ≤ 100 a / g (mL)Ascaris eggs mortality rate, ≥ 95%

Bio-organic fertilizer, which is finished organic fertilizer, is purified by means of physical methods to reduce the moisture of manure. Today, so many organic fertilizer plants are also can produce bio organic fertilizer with same fertilizer production line

The difference between the two:

First, the presence or absence of microorganisms. Bio-organic fertilizer contains a variety of beneficial microorganisms inside, but all microorganisms in organic fertilizer after high temperature treatment substantially are killed, which is difficult to provide beneficial soil microbes.

Second, different nutrients. Organic fertilizer through high-temperature treatment, nutrient losses during treatment of high temperature.

Third, different odors. Organic fertilizer by drying, deodorizing effect of organic fertilizer is not ideal because of drying treatment. once organic fertilizer is damp, stench is issued. Bio-organic fertilizer fundamentally eliminate the odor, because it can turn uric acid into the urine bacterial protein.

Item Index of organic fertilizer technical indicators

Organic matter content (dry basis), ≥45%

Total nutrient (N + P2O5 + K2O) content (dry basis), ≥5.0%

Moisture (free water) content, ≤30%

PH pH 5.5-8.0

Heavy metal content, Ascaris eggs and E. coli mortality value indicators in organic fertilizer should be normal by governmental requirements.

Technical requirements for bio-organic fertilizer

Item Index

The effective number of viable cells (cfu), ≥ 0.20 g/ one hundred million

Organic matter (dry basis), ≥ 40.0%

Moisture, ≤ 30.0%

pH value of 5.5 to 8.5

Fecal coliform, ≤ 100 a / g (mL)

Organic Methods of Pest and Disease Management

Vegetable pests: Type-1 (Leaf eating caterpillars and borers)

Shoot borer, Fruit borer, Stem borer, Hairy caterpillar (on drum stick) and army worm of vegetable crops.

Control measures

1. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

Shoot borer, Fruit borer, Stem borer, Hairy caterpillar (on drum stick) and army worm of vegetable crops.

Control measures

1. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

Andrographis paniculata (siriyanangai)

Sida spinosa (Arivalmani Poondu)

For preparation of these decoctions, one of the above mentioned plants is taken and cut into small pieces excluding roots. One kg of this is mixed with four litres of water and placed in a mud pot. This is boiled and reduced to one litre. On cooling, 500 ml of this extract is mixed with 100 ml of soap solution and 9.4 litres of water and sprayed on the top.

2. Neem Kernel extracts 500 to 2000 ml per tank (10 litres capacity)

Neem Seed

|

Neem Seed Kernel

|

3-5 kgs of neem kernel is required for an acre. Remove the outer seed coat and use only the kernel. If the seeds are fresh, 3 kgs of kernel is sufficient. If the seeds are old 5 kgs are required. Pound the kernel gently and tie it loosely with a cotton cloth. Soak this overnight in a vessel containing 10 litres of water. After this, it is filtered. On filtering, 6-7 litres of extract can be obtained. 500-1000 ml of this extract should be diluted with 9 ½ or 9 litres of water. Before spraying khadi soap solution @ 10 ml/litre should be added to help the extract stick well to the leaf surface. This concentration of the extract can be increased or decreased depending on the intensity of pest attack.

3. Garlic, Chilli, Ginger extract 500 to 1000 ml per tank (10 litres capacity)

This is a mixture of three plant extracts. 18 grammes of garlic is taken, the outer skin is removed and made into paste. A paste of 9 grammes of green chilli and 9 grammes of ginger is made. All the three pastes are dissolved in 1 litre of water. This mixture is stirred well and filtered before spraying. 500 ml of this extract is made with 100 ml of soap solution and 9.4 litres of water and sprayed on the top.

Vegetable pests: Type-2 (Sucking borers)

Aphids, Green plant hoppers, mealy bugs and white fly

Control measures

1. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

2. Neem Kernel extract 500 to 2000 ml per tank (10 litres capacity)

3. Garlic, Chilli, Ginger extract 500 to 1000 ml per tank (10 litres capacity)

(Preparation mentioned in vegetable pest type-1)

Vegetable pests: Type-3 (Beetles and bugs): Leaf beetle (pumpkin beetle), pod sucking bug, Epilachina beetles of vegetables

Control measures

1. Cow dung extract: Take 1 kg and mix it with 10 litres of water. Filter the extract with a gunny cloth. Add 5 litres of water to the filtrate and again filter it with the same cloth. The filtrate will be a very clear solution. Spray the filtrate on the plants.

2. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

3. Neem Kernel extract 500 to 2000 ml per tank (10 litres capacity)

(Preparation mentioned in vegetable pest type-1)

Vegetable diseases: Tomato wilt, Fusarium wilt in Chilli, Cercospora leaf spot, Yellow mosaic viral disease, alternaria leaf spot and fruit rot of all vegetable crops

Control methods

1. General methods

a. 10 % cow’s urine is sprayed once in 10 days thrice.

b. Half litre cow’s urine along with ½ litre sour butter milk is mixed with 9 litres of water. This is sparyed once in 7 days twice.

C. Cow’s urine and water is mixed in the ratio 1:2. The seeds or roots of seedlings are soaked in this for half an hour before sowing or transplanting .

d. 40 kgs of neem cake per acre is applied as basal manure for vegetable crops to prevent diseases.

e. If there is a disease attack in the nursery, then add 10 % cow’s urine extract along with the water that is used to irrigate the nursery.

2. Fumigation combined with other organic methods

3. Garlic, Chilli, Ginger extract 500 to 1000 ml per tank (10 litres capacity)

This is a mixture of three plant extracts. 18 grammes of garlic is taken, the outer skin is removed and made into paste. A paste of 9 grammes of green chilli and 9 grammes of ginger is made. All the three pastes are dissolved in 1 litre of water. This mixture is stirred well and filtered before spraying. 500 ml of this extract is made with 100 ml of soap solution and 9.4 litres of water and sprayed on the top.

Vegetable pests: Type-2 (Sucking borers)

Aphids, Green plant hoppers, mealy bugs and white fly

Control measures

1. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

2. Neem Kernel extract 500 to 2000 ml per tank (10 litres capacity)

3. Garlic, Chilli, Ginger extract 500 to 1000 ml per tank (10 litres capacity)

(Preparation mentioned in vegetable pest type-1)

Vegetable pests: Type-3 (Beetles and bugs): Leaf beetle (pumpkin beetle), pod sucking bug, Epilachina beetles of vegetables

Control measures

1. Cow dung extract: Take 1 kg and mix it with 10 litres of water. Filter the extract with a gunny cloth. Add 5 litres of water to the filtrate and again filter it with the same cloth. The filtrate will be a very clear solution. Spray the filtrate on the plants.

2. Andrographis paniculata (siriyanangai) decoction 3 to 5 % or Sida spinosa (Arivalmani Poondu) decoction 5 %

3. Neem Kernel extract 500 to 2000 ml per tank (10 litres capacity)

(Preparation mentioned in vegetable pest type-1)

Vegetable diseases: Tomato wilt, Fusarium wilt in Chilli, Cercospora leaf spot, Yellow mosaic viral disease, alternaria leaf spot and fruit rot of all vegetable crops

Control methods

1. General methods

a. 10 % cow’s urine is sprayed once in 10 days thrice.

b. Half litre cow’s urine along with ½ litre sour butter milk is mixed with 9 litres of water. This is sparyed once in 7 days twice.

C. Cow’s urine and water is mixed in the ratio 1:2. The seeds or roots of seedlings are soaked in this for half an hour before sowing or transplanting .

d. 40 kgs of neem cake per acre is applied as basal manure for vegetable crops to prevent diseases.

e. If there is a disease attack in the nursery, then add 10 % cow’s urine extract along with the water that is used to irrigate the nursery.

2. Fumigation combined with other organic methods

Embelica ribes (Vaividanga)

|

Acorus calamus (Vasambu)

|

10 % cow’s urine extract should be sprayed for crops affected by diseases. On the same day or the next day, fumigation should be done in the evening. Embelica ribes (Vaividanga) is powdered well (200 grammes/acre). It is then put in a wide mouthed pot with burning charcoal and carried in the field in a direction opposite to the wind. On the 7th day after fumigation, 300 ml of Acorus calamus (Vasambu) extract along with one litre of cow’s urine is mixed with 8.7 litres of water (measurement for one tank) and sprayed on the crop. Vasambu powder in 2 litres of water and then filtering the same. This method prevents wilting in chilli.

Non chemical other pest control methods

1. Light trap

Non chemical other pest control methods

1. Light trap

Light trap

Light traps can be used to monitor and trap the adults thereby reducing the population. Some common light traps that could be used are hurricane lamp, trap with electrical bulb etc., The adult moths have an inherient capacity to get attracted to the light. It should be set up in the field after 5.30 p.m. A large plate or vessel fitted with kerosene mixed water is kept near the light trap. The attracted moths falls in this water and die.

2. Yellow sticky trap

2. Yellow sticky trap

Yellow sticky trap

Castor oil smeared yellow colour empty tins or plates are kept in the field. White flies get trapped on these sticky traps. These are wiped out every day and castor oil is applied again.

3. Bird perches: Install ‘T’ shaped bird perches which are long dried twigs @15-20 per acre. These attract birds for resting and the resting birds devour the larvae in the field.

4. Hand picking method: This method of pest is useful if the crop is in a small area. Pour a small amount of kerosene in a polythene bag and pick up the larvae during evening hours and put it in the bag. The pests can be controlled this way without the use of any chemicals. This should be done when the pest numbers are low.

3. Bird perches: Install ‘T’ shaped bird perches which are long dried twigs @15-20 per acre. These attract birds for resting and the resting birds devour the larvae in the field.

4. Hand picking method: This method of pest is useful if the crop is in a small area. Pour a small amount of kerosene in a polythene bag and pick up the larvae during evening hours and put it in the bag. The pests can be controlled this way without the use of any chemicals. This should be done when the pest numbers are low.

Hand picking of larva: Wild grasses and weeds should be removed from the field bunds and field, since, these are the favourite egg laying spots of the pests.

5. Neem as pest repellent:Take neem leaves or Neem cake or Neem kernels and pound it well and place it in a pot. Add twice the volume of water and tie the mouth of the pot with a cloth. Leave it as such for three days. Then, place the pots on all the 4 corners of a field. In the evening, open the mouth of the pots. The foul smell emanating from the neem products prevents entry of pests into the field.

Silicate solubilizing bacteria (SSB)

Select an area of 40 m2 (20m x 2m) near a water source which is directly exposed to sunlight.

Make a bund all around the plot to a height of 15 cm and give it a coating with mud to prevent loss of water due to percolation.

The floating algal flasks are green or blue green in colour. From each harvest, 30 to 40 kg of dry algal flakes are obtained from the plot.

Method of inoculation of BGA in rice field

Blue green algae may be applied as soil based inoculum to the rice field following the method described below.

A week after BGA inoculation, algal growth can be seen and algal mat will float on the water after 2-3 weeks. The algal mat colour will be green or brown or yellowish green.

5. Neem as pest repellent:Take neem leaves or Neem cake or Neem kernels and pound it well and place it in a pot. Add twice the volume of water and tie the mouth of the pot with a cloth. Leave it as such for three days. Then, place the pots on all the 4 corners of a field. In the evening, open the mouth of the pots. The foul smell emanating from the neem products prevents entry of pests into the field.

Biofertilizers

Biofertilizers are defined as preparations containing living cells or latent cells of efficient strains of microorganisms that help crop plants’ uptake of nutrients by their interactions in the rhizosphere when applied through seed or soil. They accelerate certain microbial processes in the soil which augment the extent of availability of nutrients in a form easily assimilated by plants.

Very often microorganisms are not as efficient in natural surroundings as one would expect them to be and therefore artificially multiplied cultures of efficient selected microorganisms play a vital role in accelerating the microbial processes in soil.

Use of biofertilizers is one of the important components of integrated nutrient management, as they are cost effective and renewable source of plant nutrients to supplement the chemical fertilizers for sustainable agriculture. Several microorganisms and their association with crop plants are being exploited in the production of biofertilizers. They can be grouped in different ways based on their nature and function.

| S. No. | Groups | Examples |

| N2 fixing Biofertilizers | ||

| 1. | Free-living | Azotobacter, Beijerinkia, Clostridium, Klebsiella, Anabaena, Nostoc, |

| 2. | Symbiotic | Rhizobium, Frankia, Anabaena azollae |

| 3. | Associative Symbiotic | Azospirillum |

| P Solubilizing Biofertilizers | ||

| 1. | Bacteria | Bacillus megaterium var. phosphaticum, Bacillus subtilis Bacillus circulans, Pseudomonas striata |

| 2. | Fungi | Penicillium sp, Aspergillus awamori |

| P Mobilizing Biofertilizers | ||

| 1. | Arbuscular mycorrhiza | Glomus sp.,Gigaspora sp.,Acaulospora sp., Scutellospora sp. & Sclerocystis sp. |

| 2. | Ectomycorrhiza | Laccaria sp., Pisolithus sp., Boletus sp., Amanita sp. |

| 3. | Ericoid mycorrhizae | Pezizella ericae |

| 4. | Orchid mycorrhiza | Rhizoctonia solani |

| Biofertilizers for Micro nutrients | ||

| 1. | Silicate and Zinc solubilizers | Bacillus sp. |

| Plant Growth Promoting Rhizobacteria | ||

| 1. | Pseudomonas | Pseudomonas fluorescens |

| Rhizobium | |

Rhizobium is a soil habitat bacterium, which can able to colonize the legume roots and fixes the atmospheric nitrogen symbiotically. The morphology and physiology of Rhizobium will vary from free-living condition to the bacteroid of nodules. They are the most efficient biofertilizer as per the quantity of nitrogen fixed concerned. They have seven genera and highly specific to form nodule in legumes, referred as cross inoculation group.

Rhizobium inoculant was first made in USA and commercialized by private enterprise in 1930s and the strange situation at that time has been chronicled by Fred (1932).

Initially, due to absence of efficient bradyrhizobial strains in soil, soybean inoculation at that time resulted in bumper crops but incessant inoculation during the last four decades by US farmers has resulted in the build up of a plethora of inefficient strains in soil whose replacement by efficient strains of bradyrhizobia has become an insurmountable problem.

|

| Azotobacter | |

Of the several species of Azotobacter, A. chroococcum happens to be the dominant inhabitant in arable soils capable of fixing N2 (2-15 mg N2 fixed /g of carbon source) in culture media.

The bacterium produces abundant slime which helps in soil aggregation. The numbers of A. chroococcum in Indian soils rarely exceeds 105/g soil due to lack of organic matter and the presence of antagonistic microorganisms in soil.

|

| Azospirillum | |

Azospirillum lipoferum and A. brasilense (Spirillum lipoferum in earlier literature) are primary inhabitants of soil, the rhizosphere and intercellular spaces of root cortex of graminaceous plants. They perform the associative symbiotic relation with the graminaceous plants.

The bacteria of Genus Azospirillum are N2 fixing organisms isolated from the root and above ground parts of a variety of crop plants. They are Gram negative, Vibrio or Spirillum having abundant accumulation of polybetahydroxybutyrate (70 %) in cytoplasm.

Five species of Azospirillum have been described to date A. brasilense, A.lipoferum, A.amazonense, A.halopraeferens and A.irakense. The organism proliferates under both anaerobic and aerobic conditions but it is preferentially micro-aerophilic in the presence or absence of combined nitrogen in the medium.

Apart from nitrogen fixation, growth promoting substance production (IAA), disease resistance and drought tolerance are some of the additional benefits due to Azospirillum inoculation.

| |

| Cyanobacteria | |

Both free-living as well as symbiotic cyanobacteria (blue green algae) have been harnessed in rice cultivation in India. A composite culture of BGA having heterocystous Nostoc, Anabaena, Aulosira etc. is given as primary inoculum in trays, polythene lined pots and later mass multiplied in the field for application as soil based flakes to the rice growing field at the rate of 10 kg/ha. The final product is not free from extraneous contaminants and not very often monitored for checking the presence of desiredalgal flora.

Once so much publicized as a biofertilizer for the rice crop, it has not presently attracted the attention of rice growers all over India except pockets in the Southern States, notably Tamil Nadu. The benefits due to algalization could be to the extent of 20-30 kg N/ha under ideal conditions but the labour oriented methodology for the preparation of BGA biofertilizer is in itself a limitation. Quality control measures are not usually followed except perhaps for random checking for the presence of desired species qualitatively.

|

Azolla

Azolla is a free-floating water fern that floats in water and fixes atmospheric nitrogen in association with nitrogen fixing blue green alga Anabaena azollae. Azolla fronds consist of sporophyte with a floating rhizome and small overlapping bi-lobed leaves and roots. Rice growing areas in South East Asia and other third World countries have recently been evincing increased interest in the use of the symbiotic N2 fixing water fern Azolla either as an alternate nitrogen sources or as a supplement to commercial nitrogen fertilizers. Azolla is used as biofertilizer for wetland rice and it is known to contribute 40-60 kg N/ha per rice crop.

Phosphate solubilizing microorganisms(PSM)

Several soil bacteria and fungi, notably species of Pseudomonas, Bacillus, Penicillium, Aspergillusetc. secrete organic acids and lower the pH in their vicinity to bring about dissolution of bound phosphates in soil. Increased yields of wheat and potato were demonstrated due to inoculation of peat based cultures of Bacillus polymyxa and Pseudomonas striata. Currently, phosphate solubilizers are manufactured by agricultural universities and some private enterprises and sold to farmers through governmental agencies. These appear to be no check on either the quality of the inoculants marketed in India or the establishment of the desired organisms in the rhizosphere.

|

AM fungi

The transfer of nutrients mainly phosphorus and also zinc and sulphur from the soil milleu to the cells of the root cortex is mediated by intracellular obligate fungal endosymbionts of the genera Glomus, Gigaspora, Acaulospora, Sclerocysts and Endogone which possess vesicles for storage of nutrients and arbuscles for funneling these nutrients into the root system. By far, the commonest genus appears to be Glomus, which has several species distributed in soil.

Availability for pure cultures of AM (Arbuscular Mycorrhiza) fungi is an impediment in large scale production despite the fact that beneficial effects of AM fungal inoculation to plants have been repeatedly shown under experimental conditions in the laboratory especially in conjunction with other nitrogen fixers.

|

Silicate solubilizing bacteria (SSB)

Microorganisms are capable of degrading silicates and aluminum silicates. During the metabolism of microbes several organic acids are produced and these have a dual role in silicate weathering. They supply H+ ions to the medium and promote hydrolysis and the organic acids like citric, oxalic acid, Keto acids and hydroxy carbolic acids which from complexes with cations, promote their removal and retention in the medium in a dissolved state.

The studies conducted with a Bacillus sp. isolated from the soil of granite crusher yard showed that the bacterium is capable of dissolving several silicate minerals under in vitro condition. The examination of anthrpogenic materials like cement, agro inputs like super phosphate and rock phosphate exhibited silicate solubilizing bacteria to a varying degree. The bacterial isolates made from different locations had varying degree of silicate solubilizing potential. Soil inoculation studies with selected isolate with red soil, clay soil, sand and hilly soil showed that the organisms multiplied in all types of soil and released more of silica and the available silica increased in soil and water. Rice responded well to application of organic sliceous residue like rice straw, rice husk and black ash @ 5 t/ha. Combining SSB with these residues further resulted in increased plant growth and grain yield. This enhancement is due to increased dissolution of silica and nutrients from the soil.

Plant Growth Promoting Rhizobacteria (PGPR)

The group of bacteria that colonize roots or rhizosphere soil and beneficial to crops are referred to as plant growth promoting rhizobacteria (PGPR).

The PGPR inoculants currently commercialized that seem to promote growth through at least one mechanism; suppression of plant disease (termed Bioprotectants), improved nutrient acquisition (termed Biofertilizers), or phytohormone production (termed Biostimulants). Species of Pseudomonas and Bacillus can produce as yet not well characterized phytohormones or growth regulators that cause crops to have greater amounts of fine roots which have the effect of increasing the absorptive surface of plant roots for uptake of water and nutrients. These PGPR are referred to as Biostimulants and the phytohormones they produce include indole-acetic acid, cytokinins, gibberellins and inhibitors of ethylene production.

Recent advances in molecular techniques also are encouraging in that tools are becoming available to determine the mechanism by which crop performance is improved using PGPR and track survival and activity of PGPR organisms in soil and roots. The science of PGPR is at the stage where genetically modified PGPR can be produced. PGPR with antibiotic, phytohormone and siderophore production can be made.

Despite of promising results, biofertilizers has not got widespread application in agriculture mainly because of the variable response of plant species or genotypes to inoculation depending on the bacterial strain used. Differential rhizosphere effect of crops in harbouring a target strain or even the modulation of the bacterial nitrogen fixing and phosphate solubilizing capacity by specific root exudates may account for the observed differences. On the other hand, good competitive ability and high saprophytic competence are the major factors determining the success of a bacterial strain as an inoculant.

Studies to know the synergistic activities and persistence of specific microbial populations in complex environments, such as the rhizosphere, should be addressed in order to obtain efficient inoculants. In this regards, research efforts are made at Agricultural College and Research Institute, Madurai to obtain appropriate formulations of microbial inoculants incorporating nitrogen fixing, phosphate- and silicate- solubilizing bacteria and plant growth promoting rhizobacteria which will help in promoting the use of such beneficial bacteria in sustainable agriculture.

Liquid Biofertilizers

Biofertilizers are such as Rhizobium, Azospirillum and Phosphobacteria provide nitrogen and phosphorous nutrients to crop plants through nitrogen fixation and phosphorous solubilization processes. These Biofertilizers could be effectively utilized for rice, pulses, millets, cotton, sugarcane, vegetable and other horticulture crops.

Biofertilizers is one of the prime input in organic farming not only enhances the crop growth and yield but also improves the soil health and sustain soil fertility.

At present, Biofertilizers are supplied to the farmers as carrier based inoculants. As an alternative, liquid formulation technology has been developed in the Department of Agricultural Microbiology, TNAU, Coimbatore which has more advantages than the carrier inoculants.

|

Benefits

The advantages of Liquid Bio-fertilizer over conventional carrier based Bio-fertilizers are listed below:

- Longer shelf life -12-24 months.

- No contamination.

- No loss of properties due to storage upto 45º c.

- Greater potentials to fight with native population.

- High populations can be maintained more than 109 cells/ml upto 12 months to 24 months.

- Easy identification by typical fermented smell.

- Cost saving on carrier material, pulverization, neutralization, sterilization, packing and transport.

- Quality control protocols are easy and quick.

- Better survival on seeds and soil.

- No need of running Bio-fertilizer production units through out the year.

- Very much easy to use by the farmer.

- Dosages is 10 time less than carrier based powder Bio-fertilizers.

- High commercial revenues.

- High export potential.

- Very high enzymatic activity since contamination is nil.

Rhizobium

This belongs to bacterial group and the classical example is symbiotic nitrogen fixation. The bacteria infect the legume root and form root nodules within which they reduce molecular nitrogen to ammonia which is reality utilized by the plant to produce valuable proteins, vitamins and other nitrogen containing compounds. The site of symbiosis is within the root nodules. It has been estimated that 40-250 kg N / ha / year is fixed by different legume crops by the microbial activities of Rhizobium. The percentage of nodules occupied, nodules dry weight, plant dry weight and the grain yield per plant the multistrain inoculant was highly promising Table-2 shows the N fixation rates.

Quantity of biological N fixed by Liqiud Rhizobium in different crops

| Host Group | Rhizobium Species | Crops | N fix kg/ha |

| Pea group | Rhizobium leguminosarum | Green pea, Lentil | 62- 132 |

| Soybean group | R.japonicum | Soybean | 57- 105 |

| Lupini Group | R. lupine orinthopus | Lupinus | 70- 90 |

| Alfafa grp.Group | R.mellilotiMedicago Trigonella | Melilotus | 100- 150 |

| Beans group | R. phaseoli | Phaseoli | 80- 110 |

| Clover group | R. trifoli | Trifolium | 130 |

| Cowpea group | R. species | Moong, Redgram, Cowpea, Groundnut | 57- 105 |

| Cicer group | R. species | Bengal gram | 75- 117 |

Physical features of liquid Rhizobium

- Dull white in colour

- No bad smell

- No foam formation, pH 6.8-7.5