Vermicompost

Earthworms have been on the Earth for over 20 million years. In this time they have faithfully done their part to keep the cycle of life continuously moving. Their purpose is simple but very important. They are nature’s way of recycling organic nutrients from dead tissues back to living organisms. Many have recognized the value of these worms. Ancient civilizations, including Greece and Egypt valued the role earthworms played in soil. The Egyptian Pharaoh, Cleopatra said, “Earthworms are sacred.” She recognized the important role the worms played in fertilizing the Nile Valley croplands after annual floods. Charles Darwin was intrigued by the worms and studied them for 39 years. Referring to an earthworm, Darwin said, “It may be doubted whether there are many other animals in the world which have played so important a part in the history of the world.” The earthworm is a natural resource of fertility and life.

Earthworms live in the soil and feed on decaying organic material. After digestion, the undigested material moves through the alimentary canal of the earthworm, a thin layer of oil is deposited on the castings. This layer erodes over a period of 2 months. So although the plant nutrients are immediately available, they are slowly released to last longer. The process in the alimentary canal of the earthworm transforms organic waste to natural fertilizer. The chemical changes that organic wastes undergo include deodorizing and neutralizing. This means that the pH of the castings is 7 (neutral) and the castings are odorless. The worm castings also contain bacteria, so the process is continued in the soil, and microbiological activity is promoted.

Sieved finished vermicompost | Vermicompost ready for sale |

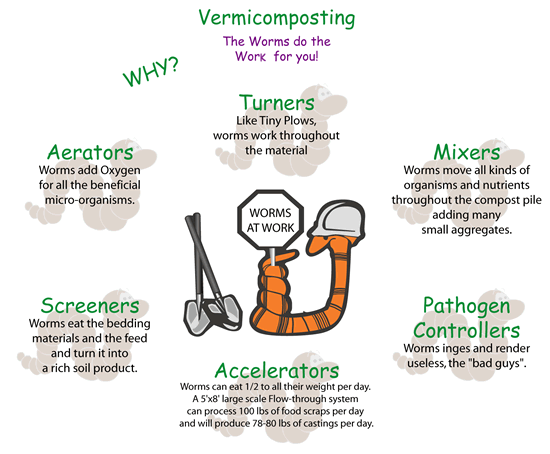

Vermicomposting is the process of turning organic debris into worm castings. The worm castings are very important to the fertility of the soil. The castings contain high amounts of nitrogen, potassium, phosphorus, calcium, and magnesium. Castings contain: 5 times the available nitrogen, 7 times the available potash, and 1 ½ times more calcium than found in good topsoil. Several researchers have demonstrated that earthworm castings have excellent aeration, porosity, structure, drainage, and moisture-holding capacity. The content of the earthworm castings, along with the natural tillage by the worms burrowing action, enhances the permeability of water in the soil. Worm castings can hold close to nine times their weight in water. “Vermiconversion,” or using earthworms to convert waste into soil additives, has been done on a relatively small scale for some time. A recommended rate of vermicompost application is 15-20 percent.

Vermicomposting is done on small and large scales. In the 1996 Summer Olympics in Sydney, Australia, the Australians used worms to take care of their tons and tons of waste.They then found that waste produced by the worms was could be very beneficial to their plants and soil. People in the U.S. have commercial vermicomposting facilities, where they raise worms and sell the castings that the worms produce. Then there are just people who own farms or even small gardens, and they may put earthworms into their compost heap, and then use that for fertilizer.

Vermicompost and its utilization

Vermicompost is nothing but the excreta of earthworms, which is rich in humus and nutrients. We can rear earthworms artificially in a brick tank or near the stem / trunk of trees (specially horticultural trees). By feeding these earthworms with biomass and watching properly the food (bio-mass) of earthworms, we can produce the required quantities of vermicompost.

Vermicompost is nothing but the excreta of earthworms, which is rich in humus and nutrients. We can rear earthworms artificially in a brick tank or near the stem / trunk of trees (specially horticultural trees). By feeding these earthworms with biomass and watching properly the food (bio-mass) of earthworms, we can produce the required quantities of vermicompost.

Any types of biodegradable wastes-

- Crop residues

- Weed biomass

- Vegetable waste

- Leaf litter

- Hotel refuse

- Waste from agro-industries

- Biodegradable portion of urban and rural wastes

Phase of vermicomposting

Phase 1

| : |

Processing involving collection of wastes, shredding, mechanical separation of the metal, glass and ceramics and storage of organic wastes.

|

Phase 2

| : |

Pre digestion of organic waste for twenty days by heaping the material along with cattle dung slurry. This process partially digests the material and fit for earthworm consumption. Cattle dung and biogas slurry may be used after drying. Wet dung should not be used for vermicompost production.

|

Phase 3

| : |

Preparation of earthworm bed. A concrete base is required to put the waste for vermicompost preparation. Loose soil will allow the worms to go into soil and also while watering, all the dissolvable nutrients go into the soil along with water.

|

Phase 4

| : |

Collection of earthworm after vermicompost collection. Sieving the composted material to separate fully composted material. The partially composted material will be again put into vermicompost bed.

|

Phase 5

| : |

Storing the vermicompost in proper place to maintain moisture and allow the beneficial microorganisms to grow.

|

What Worms Need

The Five Essentials

Compost worms need five basic things:

Compost worms need five basic things:

- An hospitable living environment, usually called “bedding”

- A food source

- Adequate moisture (greater than 50% water content by weight)

- Adequate aeration

- Protection from temperature extremes

These five essentials are discussed in more detail below.

Bedding

Bedding is any material that provides the worms with a relatively stable habitat. This habitat must have the following characteristics:

High absorbency

Worms breathe through their skins and therefore must have a moist environment in which to live. If a worm’s skin dries out, it dies. The bedding must be able to absorb and retain water fairly well if the worms are to thrive.

Good bulking potential

If the material is too dense to begin with, or packs too tightly, then the flow of air is reduced or eliminated. Worms require oxygen to live, just as we do. Different materials affect the overall porosity of the bedding through a variety of factors, including the range of particle size and shape, the texture, and the strength and rigidity of its structure. The overall effect is referred to in this document as the material’s bulking potential.

Low protein and/or nitrogen content (high Carbon: Nitrogen ratio)

Although the worms do consume their bedding as it breaks down, it is very important that this be a slow process. High protein/nitrogen levels can result in rapid degradation and its associated heating, creating inhospitable, often fatal, conditions. Heating can occur safely in the food layers of the vermiculture or vermicomposting system, but not in the bedding.

Requirements

- Housing: Sheltered culturing of worms is recommended to protect the worms from excessive sunlight and rain. All the entrepreneurs have set up their units in vacant cowsheds, poultry sheds, basements and back yards.

- Containers: Cement tanks were constructed. These were separated in half by a dividing wall. Another set of tanks were also constructed for preliminary decomposition.

- Bedding and feeding materials: During the beginning of the enterprises, most women used cowdung in order to breed sufficient numbers of earthworms. Once they have large populations, they can start using all kinds of organic waste. Half of the entrepreneurs have now reached populations of 12,000 to 15,000 adult earthworms.

i) Selection of suitable earthworm

For vermicompost production, the surface dwelling earthworm alone should be used. The earthworm, which lives below the soil, is not suitable for vermicompost production. The African earthworm (Eudrillus engenial), Red worms (Eisenia foetida) and composting worm (Peronyx excavatus) are promising worms used for vermicompost production. All the three worms can be mixed together for vermicompost production. The African worm (Eudrillus eugenial) is preferred over other two types, because it produces higher production of vermicompost in short period of time and more young ones in the composting period.

African earthworm (Eudrillus euginiae) | Tiger worm or Red wrinkle (Eisenia foetida) | Asian worms (perinonyx ecavatus) |

ii) Selection of site for vermicompost production

Vermicompost can be produced in any place with shade, high humidity and cool. Abandoned cattle shed or poultry shed or unused buildings can be used. If it is to be produced in open area, shady place is selected. A thatched roof may be provided to protect the process from direct sunlight and rain. The waste heaped for vermicompost production should be covered with moist gunny bags.

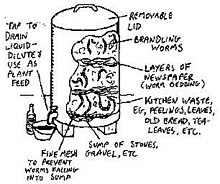

iii) Containers for vermicompost production

A cement tub may be constructed to a height of 2½ feet and a breadth of 3 feet. The length may be fixed to any level depending upon the size of the room. The bottom of the tub is made to slope like structure to drain the excess water from vermicompost unit. A small sump is necessary to collect the drain water.

In another option over the hand floor, hollow blocks / bricks may be arranged in compartment to a height of one feet, breadth of 3 feet and length to a desired level to have quick harvest. In this method, moisture assessment will be very easy. No excess water will be drained. Vermicompost can also be prepared in wooden boxes, plastic buckets or in any containers with a drain hole at the bottom.

Cement tub | Coir waste | Saw dust | Sugarcane trash |

iv) Vermiculture bed

Vermiculture bed or worm bed (3 cm) can be prepared by placing after saw dust or husk or coir waste or sugarcane trash in the bottom of tub / container. A layer of fine sand (3 cm) should be spread over the culture bed followed by a layer of garden soil (3 cm). All layers must be moistened with water.

Common Bedding Materials

Bedding Material

| Absorbency | Bulking Pot. | C:N Ratio |

| Horse Manure | Medium-Good | Good | 22 - 56 |

| Peat Moss | Good | Medium | 58 |

| Corn Silage | Medium-Good | Medium | 38 - 43 |

| Hay – general | Poor | Medium | 15 - 32 |

| Straw – general | Poor | Medium-Good | 48 - 150 |

| Straw – oat | Poor | Medium | 48 - 98 |

| Straw – wheat | Poor | Medium-Good | 100 - 150 |

| Paper from municipal waste stream | Medium-Good | Medium | 127 - 178 |

| Newspaper | Good | Medium | 170 |

| Bark – hardwoods | Poor | Good | 116 - 436 |

| Bark -- softwoods | Poor | Good | 131 - 1285 |

| Corrugated cardboard | Good | Medium | 563 |

| Lumber mill waste -- chipped | Poor | Good | 170 |

| Paper fibre sludge | Medium-Good | Medium | 250 |

| Paper mill sludge | Good | Medium | 54 |

| Sawdust | Poor-Medium | Poor-Medium | 142 - 750 |

| Shrub trimmings | Poor | Good | 53 |

| Hardwood chips, shavings | Poor | Good | 451 - 819 |

| Softwood chips, shavings | Poor | Good | 212 - 1313 |

| Leaves (dry, loose) | Poor-Medium | Poor-Medium | 40 - 80 |

| Corn stalks | Poor | Good | 60 - 73 |

| Corn cobs | Poor-Medium | Good | 56 - 123 |

| Paper mill sludge | Good | Medium | 54 |

| Sawdust | Poor-Medium | Poor-Medium | 142 - 750 |

| Shrub trimmings | Poor | Good | 53 |

| Hardwood chips, shavings | Poor | Good | 451 - 819 |

| Softwood chips, shavings | Poor | Good | 212 - 1313 |

| Leaves (dry, loose) | Poor-Medium | Poor-Medium | 40 - 80 |

| Corn stalks | Poor | Good | 60 - 73 |

| Corn cobs | Poor-Medium | Good | 56 - 123 |

If available, shredded paper or cardboard makes an excellent bedding, particularly when combined with typical on-farm organic resources such as straw and hay. Organic producers, however, must be careful to ensure that such materials are not restricted under their organic certification standards. Paper or cardboard fibre collected in municipal waste programs cannot be approved for certification purposes. There may be cases, however, where fibre resources from specific generators could be sourced and approved. This must be considered on a case-by-case basis. Another material in this category is paper-mill sludge, which has the high absorbency and small particle size that so well complements the high C:N ratios and good bulking properties of straw, bark, shipped brush or wood shavings. Again, the sludge must be approved if the user has organic certification.

In general, it should be noted by the reader that the selection of bedding materials is a key to successful vermiculture or vermicomposting. Worms can be enormously productive (and reproductive) if conditions are good; however, their efficiency drops off rapidly when their basic needs are not met (see discussion on moisture below). Good bedding mixtures are an essential element in meeting those needs. They provide protection from extremes in temperature, the necessary levels and consistency of moisture, and an adequate supply of oxygen. Fortunately, given their critical importance to the process, good bedding mixtures are generally not hard to come by on farms. The most difficult criterion to meet adequately is usually absorption, as most straws and even hay are not good at holding moisture. This can be easily addressed by mixing some aged or composted cattle or sheep manure with the straw. The result is somewhat similar in its bedding characteristics to aged horse manure.

Mixing beddings need not be an onerous process; it can be done by hand with a pitchfork (small operations), with a tractor bucket (larger operations), or, if one is available, with an agricultural feed mixer. Please note that the latter would only be appropriate for large commercial vermicomposting operations where high efficiency levels and consistent product quality is required.

v) Worm Food

Compost worms are big eaters. Under ideal conditions, they are able to consume in excess of their body weight each day, although the general rule-of-thumb is ½ of their body weight per day. They will eat almost anything organic (that is, of plant or animal origin), but they definitely prefer some foods to others. Manures are the most commonly used worm feedstock, with dairy and beef manures generally considered the best natural food for Eisenia, with the possible exception of rabbit manure. The former, being more often available in large quantities, is the feed most often used.

Common Worm Feed Stocks

| Food | Advantages | Disadvantages |

| Cattle manure | Good nutrition; natural food, therefore little adaptation required | Weed seeds make pre-composting necessary |

| Poultry manure | High N content results in good nutrition and a high-value product | High protein levels can be dangerous to worms, so must be used in small quantities; major adaptation required for worms not used to this feedstock. May be pre-composted but not necessary if used cautiously |

| Sheep/Goat manure | Good nutrition | Require pre-composting (weed seeds); small particle size can lead to packing, necessitating extra bulking material |

| Hog manure | Good nutrition; produces excellent vermicompost | Usually in liquid form, therefore must be dewatered or used with large quantities of highly absorbent bedding |

| Rabbit manure | N content second only to poultry manure, there-fore good nutrition; contains very good mix of vitamins & minerals; ideal earth-worm feed | Must be leached prior to use because of high urine content; can overheat if quantities too large; availability usually not good |

| Fresh food scraps (e.g., peels, other food prep waste, leftovers, commercial food processing wastes) | Excellent nutrition, good moisture content, possibility of revenues from waste tipping fees | Extremely variable (depending on source); high N can result in overheating; meat & high-fat wastes can create anaerobic conditions and odours, attract pests, so should NOT be included without pre-composting |

| Pre-composted food wastes | Good nutrition; partial decomposition makes digestion by worms easier and faster; can include meat and other greasy wastes; less tendency to overheat. | Nutrition less than with fresh food wastes. |

| Biosolids (human waste) | Excellent nutrition and excellent product; can be activated or non-activated sludge, septic sludge; possibility of waste management revenues | Heavy metal and/or chemical contam-ination (if from municipal sources); odour during application to beds (worms control fairly quickly); possibility of pathogen survival if process not complete |

| Seaweed | Good nutrition; results in excellent product, high in micronutrients and beneficial microbes | Salt must be rinsed off, as it is detrimental to worms; availability varies by region |

| Legume hays | Higher N content makes these good feed as well as reasonable bedding. | Moisture levels not as high as other feeds, requires more input and monitoring |

| Legume hays | Higher N content makes these good feed as well as reasonable bedding. | Moisture levels not as high as other feeds, requires more input and monitoring |

| Corrugated cardboard (including waxed) | Excellent nutrition (due to high-protein glue used to hold layers together); worms like this material; possible revenue source from WM fees | Must be shredded (waxed variety) and/or soaked (non-waxed) prior to feeding |

| Fish, poultry offal; blood wastes; animal mortalities | High N content provides good nutrition; opportunity to turn problematic wastes into high-quality product | Must be pre-composted until past thermophillic stage |

vi) Selection for vermicompost production

Cattle dung (except pig, poultry and goat), farm wastes, crop residues, vegetable market waste, flower market waste, agro industrial waste, fruit market waste and all other bio degradable waste are suitable for vermicompost production. The cattle dung should be dried in open sunlight before used for vermicompost production. All other waste should be predigested with cow dung for twenty days before put into vermibed for composting.

vii) Putting the waste in the container

The predigested waste material should be mud with 30% cattle dung either by weight or volume. The mixed waste is placed into the tub / container upto brim. The moisture level should be maintained at 60%. Over this material, the selected earthworm is placed uniformly. For one-meter length, one-meter breadth and 0.5-meter height, 1 kg of worm (1000 Nos.) is required. There is no necessity that earthworm should be put inside the waste. Earthworm will move inside on its own.

viii) Watering the vermibed

Daily watering is not required for vermibed. But 60% moisture should be maintained throughout the period. If necessity arises, water should be sprinkled over the bed rather than pouring the water. Watering should be stopped before the harvest of vermicompost.

ix) Harvesting vermicompost

In the tub method of composting, the castings formed on the top layer are collected periodically. The collection may be carried out once in a week. With hand the casting will be scooped out and put in a shady place as heap like structure. The harvesting of casting should be limited up to earthworm presence on top layer. This periodical harvesting is necessary for free flow and retain the compost quality. Other wise the finished compost get compacted when watering is done. In small bed type of vermicomposting method, periodical harvesting is not required. Since the height of the waste material heaped is around 1 foot, the produced vermicompost will be harvested after the process is over.

x) Harvesting earthworm

After the vermicompost production, the earthworm present in the tub / small bed may be harvested by trapping method. In the vermibed, before harvesting the compost, small, fresh cow dung ball is made and inserted inside the bed in five or six places. After 24 hours, the cow dung ball is removed. All the worms will be adhered into the ball. Putting the cow dung ball in a bucket of water will separate this adhered worm. The collected worms will be used for next batch of composting.

Worm harvesting is usually carried out in order to sell the worms, rather than to start new worm beds. Expanding the operation (new beds) can be accomplished by splitting the beds that is, removing a portion of the bed to start a new one and replacing the material with new bedding and feed. When worms are sold, however, they are usually separated, weighed, and then transported in a relatively sterile medium, such as peat moss. To accomplish this, the worms must first be separated from the bedding and vermicompost. There are three basic categories of methods used by growers to harvest worms: manual, migration, and mechanical. Each of these is described in more detail in the sections that follow.

a) Manual Methods

Manual methods are the ones used by hobbyists and smaller-scale growers, particularly those who sell worms to the home-vermicomposting or bait market. In essence, manual harvesting involves hand-sorting, or picking the worms directly from the compost by hand. This process can be facilitated by taking advantage of the fact that worms avoid light. If material containing worms is dumped in a pile on a flat surface with a light above, the worms will quickly dive below the surface. The harvester can then remove a layer of compost, stopping when worms become visible again. This process is repeated several times until there is nothing left on the table except a huddled mass of worms under a thin covering of compost. These worms can then be quickly scooped into a container, weighed, and prepared for delivery.

There are several minor variations and/or enhancements on this method, such as using a container instead of a flat surface, or making several piles at once, so that the person harvesting can move from one to another, returning to the first one in time to remove the next layer of compost. They are all labour-intensive, however, and only make sense if the operation is small and the value of the worms is high.

b) Self-Harvesting (Migration) Methods

These methods, like some of the methods used in vermicomposting, are based on the worms tendency to migrate to new regions, either to find new food or to avoid undesirable conditions, such as dryness or light. Unlike the manual methods described above, however, they often make use of simple mechanisms, such as screens or onion bags.

The screen method is very common and easy to use. A box is constructed with a screen bottom. The mesh is usually ¼”, although 1/8” can be used as wel. There are two different approaches. The downward-migration system is similar to the manual system, in that the worms are forced downward by strong light. The difference with the screen system is that the worms go down through the screen into a prepared, pre-weighed container of moist peat moss. Once the worms have all gone through, the compost in the box is removed and a new batch of worm-rich compost is put in. The process is repeated until the box with the peat moss has reached the desired weight. Like the manual method, this system can be set up in a number of locations at once, so that the worm harvester can move from one box to the next, with no time wasted waiting for the worms to migrate.

The upward-migration system is similar, except that the box with the mesh bottom is placed directly on the worm bed. It has been filled with a few centimeters of damp peat moss and then sprinkled with a food attractive to worms, such as chicken mash, coffee grounds, or fresh cattle manure. The box is removed and weighed after visual inspection indicates that sufficient worms have moved up into the material. This system is used extensively in Cuba, with the difference that large onion bags are used instead of boxes. The advantage of this system is that the worm beds are not disturbed. The main disadvantage is that the harvested worms are in material that contains a fair amount of unprocessed food, making the material messier and opening up the possibility of heating inside the package if the worms are shipped. The latter problem can be avoided by removing any obvious food and allowing a bit of time for the worms to consume what is left before packaging.

xi) Nutritive value of vermicompost

The nutrients content in vermicompost vary depending on the waste materials that is being used for compost preparation. If the waste materials are heterogeneous one, there will be wide range of nutrients available in the compost. If the waste materials are homogenous one, there will be only certain nutrients are available. The common available nutrients in vermicompost is as follows

Organic carbon

|

:

|

9.5 – 17.98%

|

Nitrogen

|

:

|

0.5 – 1.50%

|

Phosphorous

|

:

|

0.1 – 0.30%

|

Potassium

|

:

|

0.15 – 0.56%

|

Sodium

|

:

|

0.06 – 0.30%

|

Calcium and Magnesium

|

:

|

22.67 to 47.60 meq/100g

|

Copper

|

:

|

2 – 9.50 mg kg-1

|

Iron

|

:

|

2 – 9.30 mg kg-1

|

Zinc

|

:

|

5.70 – 11.50 mg kg-1

|

Sulphur

|

:

|

128 – 548 mg kg-1

|

xii) Storing and packing of vermicompost

The harvested vermicompost should be stored in dark, cool place. It should have minimum 40% moisture. Sunlight should not fall over the composted material. It will lead to loss of moisture and nutrient content. It is advocated that the harvested composted material is openly stored rather than packed in over sac. Packing can be done at the time of selling. If it is stored in open place, periodical sprinkling of water may be done to maintain moisture level and also to maintain beneficial microbial population. If the necessity comes to store the material, laminated over sac is used for packing. This will minimize the moisture evaporation loss. Vermicompost can be stored for one year without loss of its quality, if the moisture is maintained at 40% level.

The harvested vermicompost should be stored in dark, cool place. It should have minimum 40% moisture. Sunlight should not fall over the composted material. It will lead to loss of moisture and nutrient content. It is advocated that the harvested composted material is openly stored rather than packed in over sac. Packing can be done at the time of selling. If it is stored in open place, periodical sprinkling of water may be done to maintain moisture level and also to maintain beneficial microbial population. If the necessity comes to store the material, laminated over sac is used for packing. This will minimize the moisture evaporation loss. Vermicompost can be stored for one year without loss of its quality, if the moisture is maintained at 40% level.

- Vermicompost is rich in all essential plant nutrients.

- Provides excellent effect on overall plant growth, encourages the growth of new

- shoots / leaves and improves the quality and shelf life of the produce.

- Vermicompost is free flowing, easy to apply, handle and store and does not have bad

- odour.

- It improves soil structure, texture, aeration, and waterholding capacity and prevents

- soil erosion.

- Vermicompost is rich in beneficial micro flora such as a fixers, P- solubilizers,

- cellulose decomposing micro-flora etc in addition to improve soil environment.

- Vermicompost contains earthworm cocoons and increases the population and

- activity of earthworm in the soil.

- It neutralizes the soil protection.

- It prevents nutrient losses and increases the use efficiency of chemical fertilizers.

- Vermicompost is free from pathogens, toxic elements, weed seeds etc.

- Vermicompost minimizes the incidence of pest and diseases.

- It enhances the decomposition of organic matter in soil.

- It contains valuable vitamins, enzymes and hormones like auxins, gibberellins etc.

Compost worms are not subject to diseases caused by micro-organisms, but they are subject to predation by certain animals and insects (red mites are the worst) and to a disease known as “sour crop” caused by environmental conditions.

Vermicomposting is a type of composting in which certain species of earthworms are used to enhance the process of organic waste conversion and produce a better end-product. It is a mesophilic process utilizing microorganisms and earthworms. Earthworms feeds the organic waste materials and passes it through their digestive system and gives out in a granular form (cocoons) which is known as vermicompost.

Simply speaking, vermicompost is earthworm excrement, called castings, which can improve biological, chemical, and physical properties of the soil. The chemical secretions in the earthworm’s digestive tract help break down soil and organic matter, so the castings contain more nutrients that are immediately available to plants.

How is Vermicompost Produced

A wide range of organic residues, such as straw, husk, leaves, stalks, weeds etc can be converted into vermicompost. Other potential feedstock for vermicompost production are livestock wastes, poultry litter, dairy wastes, food processing wastes, organic fraction of MSW, bagasse, digestate from biogas plants etc. Earthworms consume organic wastes and reduce the volume by 40–60 percent. Each earthworm weighs about 0.5 to 0.6 gram, eats waste equivalent to its body weight and produces cast equivalent to about 50 percent of the waste it consumes in a day. The moisture content of castings ranges between 32 and 66 percent and the pH is around 7. The level of nutrients in compost depends upon the source of the raw material and the species of earthworm.

There are nearly 3600 types of earthworms which are divided into burrowing and non-burrowing types. Red earthworm species, like Eisenia foetida, and are most efficient in compost making. The non-burrowing earthworms eat 10 percent soil and 90 percent organic waste materials; these convert the organic waste into vermicompost faster than the burrowing earthworms. They can tolerate temperatures ranging from 0 to 40°C but the regeneration capacity is more at 25 to 30°C and 40–45 percent moisture level in the pile. The burrowing types of earthworms come onto the soil surface only at night. These make holes in the soil up to a depth of 3.5 m and produce 5.6 kg casts by ingesting 90 percent soil and 10 percent organic waste.

A commercial vermicomposting facility in Avon, New York

The types of vermicomposting depend upon the amount of producton and composting structures. Small-scale vermicomposting is done to meet personal requirements and farmers/gardeners can harvest 5-10 tons of vermicompost annually. On the other hand, large-scale vermicomposting is done at commercial scale by recycling large quantities of organic waste in modern facilities with the production of more than hundreds of tons annually.

Applications of Vermicompost

The worm castings contain higher percentage of both macro and micronutrients than the garden compost. Apart from other nutrients, a fine worm cast is rich in NPK which are in readily available form and are released within a month of application. Vermicompost enhances plant growth, suppresses disease in plants, increases porosity and microbial activity in soil, and improves water retention and aeration.

Vermicompost also benefits the environment by reducing the need for chemical fertilizers and decreasing the amount of waste going to landfills. Vermicompost production is trending up worldwide and it is finding increasing use especially in Western countries, Asia-Pacific and Southeast Asia.

A relatively new product from vermicomposting is vermicompost tea which is a liquid produced by extracting organic matter, microorganisms, and nutrients from vermicompost. Unlike vermicompost and compost, this tea may be applied directly to plant foliage, reportedly to enhance disease suppression. Vermicompost tea also may be applied to the soil as a supplement between compost applications to increase biological activity.

Vermicompost may be sold in bulk or bagged with a variety of compost and soil blends. Markets include home improvement centers, nurseries, landscape contractors, greenhouses, garden supply stores, grocery chains, flower shops, discount houses, and the general public.

Vermicompost - Production and Practices

Vermicomposting is a method of preparing enriched compost with the use of

earthworms. It is one of the easiest methods to recycle agricultural wastes and to

produce quality compost. Earthworms consume biomass and excrete it in digested

form called worm casts. Worm casts are popularly called as Black gold. The casts

are rich in nutrients, growth promoting substances, beneficial soil micro flora and

having properties of inhibiting pathogenic microbes.

Vermicompost is stable, fine granular organic manure, which enriches soil quality by

improving its physicochemical and biological properties. It is highly useful in raising

seedlings and for crop production. Vermicompost is becoming popular as a major

component of organic farming system.

Vermicomposting materials

Decomposable organic wastes such as animal excreta, kitchen waste, farm residues

and forest litter are commonly used as composting materials. In general, animal dung

mostly cow dung and dried chopped crop residues are the key raw materials. Mixture

of leguminous and non-leguminous crop residues enriches the quality of

vermicompost.

There are different species of earthworms viz. Eisenia foetida (Red earthworm),

Eudrilus eugeniae (night crawler), Perionyx excavatus etc. Red earthworm is

preferred because of its high multiplication rate and thereby converts the organic

matter into vermicompost within 45-50 days. Since it is a surface feeder it converts

organic materials into vermicompost from top.

Important characteristics of red earthworm (Eisenia foetida)

Characters Eisenia foetida

Body length 3-10cm

Body weight 0.4-0.6g

Maturity 50-55days

Conversion rate 2.0 q/1500worms/2 months

Cocoon production 1 in every 3 days

Incubation of cocoon 20-23days

Types of vermicomposting

The types of vermicomposting depend upon the amount of producton and composting

structures. Small-scale vermicomposting is done to meet the personal requirement and

farmer can harvest 5-10 tonnes of vermicompost annually. While, large-scale

vermicomposting is done at commercial scale by recycling large quantity of organic

waste with the production of more than 50 – 100 tonnes annually

Methods of vermicomposting

Vermicromposting is done by various

methods, among them bed and pit

methods are more common.

Bed method : Composting is done on the

pucca / kachcha floor by making bed

(6x2x2 feet size) of organic mixture. This method is easy to maintain and to practice

(Fig.1).

Pit method: Composting is done in the

cemented pits of size 5x5x3 feet. The unit is

covered with thatch grass or any other locally

available materials. This method is not

preferred due to poor aeration, water logging at

bottom, and more cost of production (fig.2)

Process of vermicomposting

Following steps are followed for vermicompost preparation

• Vermicomposting unit should be in a cool, moist and shady site

• Cow dung and chopped dried leafy materials are mixed in the proportion of 3: 1

and are kept for partial decomposition for 15 – 20 days.

• A layer of 15-20cm of chopped dried leaves/grasses should be kept as bedding

material at the bottom of the bed.

• Beds of partially decomposed material of size 6x2x2 feet should be made (fig.3).

• Each bed should contain 1.5-2.0q of raw material and the number of beds can be

increased as per raw material availability and requirement.

• Red earthworm (1500-2000) should be released on the upper layer of bed (fig.4).

• Water should be sprinkled with can immediately after the release of worms (fig.5)

• Beds should be kept moist by sprinkling of water (daily) and by covering with

gunny bags/polythene (fig.6)

• Bed should be turned once after 30 days for maintaining aeration and for proper

decomposition.

• Compost gets ready in 45-50 days (fig.7).

• The finished product is 3/4th of the raw materials used.

Harvesting

When raw material is completely decomposed it appears black and granular. Watering

should be stopped as compost gets ready. The compost shout be kept over a heap of

partially decomposed cow dung so that earthworms could migrate to cow dung from

compost (fig.7). After two days compost can be separated and sieved for use (fig.8).

Preventive measures

• The floor of the unit should be compact to prevent earthworms’ migration into

the soil.

• 15-20 days old cow dung should be used to avoid excess heat.

• The organic wastes should be free from plastics, chemicals, pesticides and

metals etc.

• Aeration should be maintained for proper growth and multiplication of

earthworms.

• Optimum moisture level (30-40 %) should be maintained

• 18-25oC temperature should be maintained for proper decomposition.

Nutrient content of vermicompost

The level of nutrients in compost depends upon the source of the raw material and the

species of earthworm. A fine worm cast is rich in N P K besides other nutrients.

Nutrients in vermicompost are in readily available form and are released within a

month of application.

Nutrient Analysis of Vermicompost

Parameters Content

pH 6.8

OC% 11.88

OM% 20.46

C/N ration 11.64

Total Nitrogen (%) 1.02

Available N (%) 0.50

Available P (%) 0.30

Available K (%) 0.24

Ca (%) 0.17

Mg (%) 0.06

Advantages

There are many advantages of vermicompost :

• It provides efficient conversion of organic wastes/crop/animal residues.

• It is a stable and enriched soil conditioner.

• It helps in reducing population of pathogenic microbes.

• It helps in reducing the toxicity of heavy metals.

• It is economically viable and environmentally safe nutrient supplement for

organic food production.

• It is an easily adoptable low cost technology.

Doses

The doses of vermicompost application depend upon the type of crop grown in the

field/nursery. For fruit crops, it is applied in the tree basin. It is added in the pot

mixture for potted ornamental plants and for raising seedlings. Vermicompost should

be used as a component of integrated nutrient supply system.

Crops Dose/rate

Field crops 5-6t/ha

Fruit crops 3-5kg/plant

Pots 100-200g/pot

Benefit

Vermicomposting is a highly profitable venture for farmers having dairy units. The

approximate cost and benefit under different scale of production is given below.

Scale App.cost per App.benefit per Cost/benefit ratio

annum (Rs) annum (Rs)

Small 52,000 90,000 1 : 1.73

Medium 1.0 lakh 1.85 lakh 1 : 1.85

Large 2.25 lakh 4.5 lakh 1 : 2.0

Published by

ICAR Research Complex for NEH Region,

Umiam – 793 103, Meghalaya

For Further information contact

Joint Director,

ICAR Research Complex for NEH Region, Mizoram Centre

Kolasib – 796081, Mizoram

Vermicompost (vermi-compost, vermiculture) is the product of the decomposition process using various species of worms, usually red wigglers, white worms, and other earthworms, to create a mixture of decomposing vegetable or food waste, bedding materials, and vermicast.

Vermicast (also called worm castings, worm humus, worm manure, or worm feces) is the end-product of the breakdown of organic matter by earthworms.[1] These castings have been shown to contain reduced levels of contaminants and a higher saturation of nutrients than the organic materials before vermicomposting.[2]

Vermicompost contains water-soluble nutrients and is an excellent, nutrient-rich organic fertilizer and soil conditioner.[3] It is used in farming and small scale sustainable, organic farming.

Vermicomposting can also be applied for treatment of sewage.[4] A variation of the process is vermifiltration (or vermidigestion) which is used to remove organic matter, pathogens and oxygen demand from wastewater or directly from blackwater of flush toilets.[5][6]

Contents

Overview[edit]

Vermicomposting has gained popularity in both industrial and domestic settings because, as compared with conventional composting, it provides a way to treat organic wastes more quickly. In manure composting, it also generates products that have lower salinity levels.[7]

The earthworm species (or composting worms) most often used are red wigglers (Eisenia fetida or Eisenia andrei), though European nightcrawlers (Eisenia hortensis or Dendrobaena veneta) could also be used. Red wigglers are recommended by most vermicomposting experts, as they have some of the best appetites and breed very quickly. Users refer to European nightcrawlers by a variety of other names, including dendrobaenas, dendras, Dutch nightcrawlers, and Belgian nightcrawlers.

Containing water-soluble nutrients, vermicompost is a nutrient-rich organic fertilizer and soil conditioner in a form that is relatively easy for plants to absorb.[3] Worm castings are sometimes used as an organic fertilizer. Because the earthworms grind and uniformly mix minerals in simple forms, plants need only minimal effort to obtain them. The worms' digestive systems create environments that allow certain species of microbes to thrive to help create a "living" soil environment for plants.[8] The fraction of soil which has gone through the digestive tract of earthworms is called the drilosphere.[9]

Design considerations[edit]

Suitable worm species[edit]

One of the species most often used for composting is the red wiggler or tiger worm (Eisenia fetida or Eisenia andrei); Lumbricus rubellus (a.k.a. red earthworm or dilong (China)) is another breed of worm that can be used, but it does not adapt as well to the shallow compost bin as does Eisenia fetida. European nightcrawlers (Eisenia hortensis) may also be used. Users refer to European nightcrawlers by a variety of other names, including dendrobaenas, dendras, and nightcrawlers. African Nightcrawlers (Eudrilus eugeniae) are another set of popular composters. Lumbricus terrestris (a.k.a. Canadian nightcrawlers (US) or common earthworm (UK)) are not recommended, since they burrow deeper than most compost bins can accommodate.[10]

Blueworms (Perionyx excavatus) may be used in the tropics.[11]

These species commonly are found in organic-rich soils throughout Europe and North America and live in rotting vegetation, compost, and manure piles. They may be an invasive species in some areas.[1][12] As they are shallow-dwelling and feed on decomposing plant matter in the soil, they adapt easily to living on food or plant waste in the confines of a worm bin.

Composting worms are available to order online, from nursery mail-order suppliers or angling shops where they are sold as bait. They can also be collected from compost and manure piles. These species are not the same worms that are found in ordinary soil or on pavement when the soil is flooded by water.

Large scale[edit]

Large-scale vermicomposting is practiced in Canada, Italy, Japan, India, Malaysia, the Philippines, and the United States.[13] The vermicompost may be used for farming, landscaping, to create compost tea, or for sale. Some of these operations produce worms for bait and/or home vermicomposting.

There are two main methods of large-scale vermiculture. Some systems use a windrow, which consists of bedding materials for the earthworms to live in and acts as a large bin; organic material is added to it. Although the windrow has no physical barriers to prevent worms from escaping, in theory they should not due to an abundance of organic matter for them to feed on. Often windrows are used on a concrete surface to prevent predators from gaining access to the worm population.

The windrow method and compost windrow turners were developed by Fletcher Sims Jr. of the Compost Corporation in Canyon, Texas. The Windrow Composting system is noted as a sustainable, cost-efficient way for farmers to manage dairy waste.[14]

The second type of large-scale vermicomposting system is the raised bed or flow-through system. Here the worms are fed an inch of "worm chow" across the top of the bed, and an inch of castings are harvested from below by pulling a breaker bar across the large mesh screen which forms the base of the bed.

Because red worms are surface dwellers constantly moving towards the new food source, the flow-through system eliminates the need to separate worms from the castings before packaging. Flow-through systems are well suited to indoor facilities, making them the preferred choice for operations in colder climates.

Small scale[edit]

For vermicomposting at home, a large variety of bins are commercially available, or a variety of adapted containers may be used. They may be made of old plastic containers, wood, Styrofoam, or metal containers. The design of a small bin usually depends on where an individual wishes to store the bin and how they wish to feed the worms.

Some materials are less desirable than others in worm bin construction. Metal containers often conduct heat too readily, are prone to rusting, and may release heavy metals into the vermicompost. Styrofoam containers may release chemicals into the organic material.[15] Some cedars, Yellow cedar, and Redwood contain resinous oils that may harm worms,[16] although Western Red Cedar has excellent longevity in composting conditions. Hemlock is another inexpensive and fairly rot-resistant wood species that may be used to build worm bins.[17]

Bins need holes or mesh for aeration. Some people add a spout or holes in the bottom for excess liquid to drain into a tray for collection.[18]The most common materials used are plastic: recycled polyethylene and polypropylene and wood.[19] Worm compost bins made from plastic are ideal, but require more drainage than wooden ones because they are non-absorbent. However, wooden bins will eventually decay and need to be replaced.

Small-scale vermicomposting is well-suited to turn kitchen waste into high-quality soil amendments, where space is limited. Worms can decompose organic matter without the additional human physical effort (turning the bin) that bin composting requires.

Composting worms which are detritivorous (eaters of trash), such as the red wiggler Eisenia fetidae, are epigeic (surface dwellers) and together with symbiotic associated microbes are the ideal vectors for decomposing food waste. Common earthworms such as Lumbricus terrestris are anecic (deep burrowing) species and hence unsuitable for use in a closed system.[20] Other soil species that contribute include insects, other worms and molds.[21]

Climate and temperature[edit]

There may be differences in vermicomposting method depending on the climate.[22] It is necessary to monitor the temperatures of large-scale bin systems (which can have high heat-retentive properties), as the raw materials or feedstocks used can compost, heating up the worm bins as they decay and killing the worms.

The most common worms used in composting systems, redworms (Eisenia foetida, Eisenia andrei, and Lumbricus rubellus) feed most rapidly at temperatures of 15–25 °C (59-77 °F). They can survive at 10 °C (50 °F). Temperatures above 30 °C (86 °F) may harm them.[23] This temperature range means that indoor vermicomposting with redworms is possible in all but tropical climates. Other worms like Perionyx excavatus are suitable for warmer climates.[24] If a worm bin is kept outside, it should be placed in a sheltered position away from direct sunlight and insulated against frost in winter.

Feedstock[edit]

There are few food wastes that vermicomposting cannot compost, although meat waste and dairy products are likely to putrefy, and in outdoor bins can attract vermin. Green wasteshould be added in moderation to avoid heating the bin.

Small-scale or home systems[edit]

Such systems usually use kitchen and garden waste, using "earthworms and other microorganisms to digest organic wastes, such as kitchen scraps".[25] This includes:

- All fruits and vegetables (including citrus, in limited quantities)

- Vegetable and fruit peels and ends

- Coffee grounds and filters

- Tea bags (even those with high tannin levels)

- Grains such as bread, cracker and cereal (including moldy and stale)

- Eggshells (rinsed off)

- Leaves and grass clippings (not sprayed with pesticides[26])

- Newspapers (most inks used in newspapers are not toxic)

- Paper toweling (which has not been used with cleaners or chemicals)

Large-scale or commercial[edit]

Such vermicomposting systems need reliable sources of large quantities of food. Systems presently operating[27] use:

- Dairy cow or pig manure Sewage sludge[28][29]

- Brewery waste

- Cotton mill waste

- Agricultural waste

- Food processing and grocery waste

- Cafeteria waste

- Grass clippings and wood chips

Harvesting[edit]

Vermicompost is ready for harvest when it contains few-to-no scraps of uneaten food or bedding.[25] There are several methods of harvesting from small-scale systems: "dump and hand sort", "let the worms do the sorting", "alternate containers" and "divide and dump."[30] These differ on the amount of time and labor involved and whether the vermicomposter wants to save as many worms as possible from being trapped in the harvested compost.

The pyramid method of harvesting worm compost is commonly used in small-scale vermiculture, and is considered the simplest method for single layer bins.[31] In this process, compost is separated into large clumps, which is placed back into composting for further breakdown, and lighter compost, with which the rest of the process continues. This lighter mix is placed into small piles on a tarp under the sunlight. The worms instinctively burrow to the bottom of the pile. After a few minutes, the top of the pyramid is removed repeatedly, until the worms are again visible. This repeats until the mound is composed mostly of worms.

When harvesting the compost, it is possible to separate eggs and cocoons and return them to the bin, thereby ensuring new worms are hatched. Cocoons are small, lemon-shaped yellowish objects that can usually be seen with the naked eye.[32] The cocoons can hold up to 20 worms (though 2-3 is most common). Cocoons can lay dormant for as long as two years if conditions are not conducive for hatching.[33]

Properties[edit]

Vermicompost has been shown to be richer in many nutrients than compost produced by other composting methods.[34] It has also outperformed a commercial plant medium with nutrients added, but levels of magnesium required adjustment, as did pH.[35]

However, in one study it has been found that homemade backyard vermicompost was lower in microbial biomass, soil microbial activity, and yield of a species of ryegrass[36] than municipal compost.[36]

It is rich in microbial life which converts nutrients already present in the soil into plant-available forms.

Unlike other compost, worm castings also contain worm mucus which helps prevent nutrients from washing away with the first watering and holds moisture better than plain soil.[37]

Increases in the total nitrogen content in vermicompost, an increase in available nitrogen and phosphorus, as well as the increased removal of heavy metals from sludge and soil have been reported.[38] The reduction in the bioavailability of heavy metals has been observed in a number of studies.[39][40]

Benefits[edit]

Soil

- Improves soil aeration

- Enriches soil with micro-organisms (adding enzymes such as phosphatase and cellulase)

- Microbial activity in worm castings is 10 to 20 times higher than in the soil and organic matter that the worm ingests [41]

- Attracts deep-burrowing earthworms already present in the soil

- Improves water holding capacity[42]

Plant growth

- Enhances germination, plant growth, and crop yield

- Improves root growth and structure

- Enriches soil with micro-organisms (adding plant hormones such as auxins and gibberellic acid)[citation needed]

Economic

- Biowastes conversion reduces waste flow to landfills

- Elimination of biowastes from the waste stream reduces contamination of other recyclables collected in a single bin (a common problem in communities practicing Single-stream recycling)

- Creates low-skill jobs at local level

- Low capital investment and relatively simple technologies make vermicomposting practical for less-developed agricultural regions

Environmental

- Helps to close the "metabolic gap" through recycling waste on-site

- Large systems often use temperature control and mechanized harvesting, however other equipment is relatively simple and does not wear out quickly[citation needed]

- Production reduces greenhouse gas emissions such as methane and nitric oxide (produced in landfills or incinerators when not composted).

Uses[edit]

Soil conditioner[edit]

Vermicompost can be mixed directly into the soil, or mixed with water to make a liquid fertilizer known as worm tea.

The dark brown waste liquid, or leachate, that drains into the bottom of some vermicomposting systems is not to be confused with worm tea.It is an uncomposted byproduct from when water-rich foods break down and may contain pathogens and toxins. It is best discarded or applied back to the bin when added moisture is needed for further processing.[43][44]

The pH, nutrient, and microbial content of these fertilizers varies upon the inputs fed to worms. Pulverized limestone, or calcium carbonate can be added to the system to raise the pH.

Operation and maintenance[edit]

Smells[edit]

When closed, a well-maintained bin is odorless; when opened, it should have little smell—if any smell is present, it is earthy.[45] The smell may also depend on the type of composted material added to the bin. An unhealthy worm bin may smell, potentially due to low oxygen conditions. Worms require gaseous oxygen.[46] Oxygen can be provided by airholes in the bin, occasional stirring of bin contents, and removal of some bin contents if they become too deep or too wet. If decomposition becomes anaerobic from excess wet feedstock added to the bin, or the layers of food waste have become too deep, the bin will begin to smell of ammonia.

Moisture[edit]

Moisture must be maintained above 50%, as lower moisture content will not support worm respiration and can increase worm mortality. Operating moisture-content range should be between 70-90%, with a suggested content of 70-80% for vermicomposting-oriented vermiculture operations.[47] If decomposition has become anaerobic, to restore healthy conditions and prevent the worms from dying, excess waste water must be reduced and the bin returned to a normal moisture level. To do this, first reduce addition of food scraps with a high moisture content and second, add fresh, dry bedding such as shredded newspaper to your bin, mixing it in well.[48]

Pest species[edit]

Pests such as rodents and flies are attracted by certain materials and odors, usually from large amounts of kitchen waste, particularly meat. Eliminating the use of meat or dairy product in a worm bin decreases the possibility of pests.[49]

Predatory ants can be a problem in African countries.[50]

In warm weather, fruit and vinegar flies breed in the bins if fruit and vegetable waste is not thoroughly covered with bedding. This problem can be avoided by thoroughly covering the waste by at least 5 centimetres (2.0 in) of bedding. Maintaining the correct pH (close to neutral) and water content of the bin (just enough water where squeezed bedding drips a couple of drops) can help avoid these pests as well.

Worms escaping[edit]

Worms generally stay in the bin, but may try to leave the bin when first introduced, or often after a rainstorm when outside humidity is high.[51] Maintaining adequate conditions in the worm bin and putting a light over the bin when first introducing worms should eliminate this problem.[52]

Nutrient levels[edit]

Commercial vermicomposters test, and may amend their products to produce consistent quality and results. Because the small-scale and home systems use a varied mix of feedstocks, the nitrogen, potassium and phosphorus content of the resulting vermicompost will also be inconsistent. NPK testing may be helpful before the vermicompost or tea is applied to the garden.

In order to avoid over-fertilization issues, such as nitrogen burn, vermicompost can be diluted as a tea 50:50 with water, or as a solid can be mixed in 50:50 with potting soil.[53]

Additionally, the mucous layer created by worms which surrounds their castings allows for a "time release" effect, meaning not all nutrients are released at once. This also reduces the risk of burning the plants, as is common with the use and overuse of commercial fertilizers.[54]

Application examples[edit]

Vermicomposting (also known as vermiculture) is widely used in North America for on-site institutional processing of food scraps, such as in hospitals, universities, shopping malls, and correctional facilities.[55] Vermicomposting is used for medium-scale on-site institutional organic material recycling, such as for food scraps from universities and shopping malls. It is selected either as a more environmentally friendly choice than conventional disposal, or to reduce the cost of commercial waste removal.

Researchers from the Pondicherry University discovered that worm composts can also be used to clean up heavy metals. The researchers found substantial reductions in heavy metals when the worms were released into the garbage and they are effective at removing lead, zinc, cadmium, copper and manganese.[56]

Vermicomposting is a type of composting in which certain species of earthworms are used to enhance the process of organic waste conversion and produce a better end-product. It is a mesophilic process utilizing microorganisms and worms. Earthworms feeds the organic waste materials and passes it through their digestive system and gives out in a granular form (cocoons) which is known as vermicompost.

Simply speaking, vermicompost is earthworm excrement, called castings, which can improve biological, chemical, and physical properties of the soil. The chemical secretions in the earthworm’s digestive tract help break down soil and organic matter, so the castings contain more nutrients that are immediately available to plants.

Production of Vermicompost

A wide range of agricultural residues, such as straw, husk, leaves, stalks, weeds etc can be converted into vermicompost. Other potential feedstock for vermicompost production are livestock wastes, poultry litter, dairy wastes, food processing wastes, organic fraction of MSW, bagasse, digestate from biogas plants etc.

Earthworms consume organic wastes and reduce the volume by 40–60 percent. Each earthworm weighs about 0.5 to 0.6 gram, eats waste equivalent to its body weight and produces cast equivalent to about 50 percent of the waste it consumes in a day. The moisture content of castings ranges between 32 and 66 percent and the pH is around 7. The level of nutrients in compost depends upon the source of the raw material and the species of earthworm.

Types of Earthworms

There are nearly 3600 types of earthworms which are divided into burrowing and non-burrowing types. Red earthworm species, like Eisenia foetida, and are most efficient in compost making. The non-burrowing earthworms eat 10 percent soil and 90 percent organic waste materials; these convert the organic waste into vermicompost faster than the burrowing earthworms.

They can tolerate temperatures ranging from 0 to 40°C but the regeneration capacity is more at 25 to 30°C and 40–45 percent moisture level in the pile. The burrowing types of earthworms come onto the soil surface only at night. These make holes in the soil up to a depth of 3.5 m and produce 5.6 kg casts by ingesting 90 percent soil and 10 percent organic waste.

Types of Vermicomposting

The types of vermicomposting depend upon the amount of production and composting structures. Small-scale vermicomposting is done to meet personal requirements and farmers/gardeners can harvest 5-10 tons of vermicompost annually.

On the other hand, large-scale vermicomposting is done at commercial scale by recycling large quantities of organic waste in modern facilities with the production of more than hundreds of tons annually.

Benefits of Vermicompost

The worm castings contain higher percentage of both macro and micronutrients than the garden compost. Apart from other nutrients, a fine worm cast is rich in NPK which are in readily available form and are released within a month of application. Vermicompost enhances plant growth, suppresses disease in plants, increases porosity and microbial activity in soil, and improves water retention and aeration.

Vermicompost also benefits the environment by reducing the need for chemical fertilizers and decreasing the amount of waste going to landfills. Vermicompost production is trending up worldwide and it is finding increasing use especially in Western countries, Asia-Pacific and Southeast Asia.

Vermicompost Tea

A relatively new product from vermicomposting is vermicompost tea which is a liquid produced by extracting organic matter, microorganisms, and nutrients from vermicompost. Unlike vermicompost and compost, this tea may be applied directly to plant foliage, reportedly to enhance disease suppression. Vermicompost tea also may be applied to the soil as a supplement between compost applications to increase biological activity.

Potential Market

Vermicompost may be sold in bulk or bagged with a variety of compost and soil blends. Markets include home improvement centers, nurseries, landscape contractors, greenhouses, garden supply stores, grocery chains, flower shops, discount houses, indoor gardens, and the general public.

Composting is an aerobic process with high temperatures, while vermicomposting is a process where worms do the work. This means that vermicomposting is a low temperature process.

Vermicomposting can be done in small bins to bathtub size vessels. The worms eat through the kitchen waste and paper that is added. It is also a moist process and any drainage is commonly used as a worm tea. Vermicomposting can be done on a larger scale, but the waste must be applied in thin layers to not to overheat the pile or overfeed the worms. Worms are sensitive animals and may take off when conditions are not right.

In composting, the minimum size is a cubic yard, otherwise the temperature will not increase high enough. Oxygen must be applied to satisfy the needs of the bacteria that do the work. This means turning and aerating. If a compost pile gets too wet or otherwise anaerobic, stink will develop. This is the issue with larger industrial facilities. Odour is the Achilles heel of the composting industry.

Municipalities and private industries are collecting food waste and yard and garden waste for composting. When food waste is a large percentage of the collected material the risk of odour is high and composting facilities need more sophistication in aeration, mixing and air and leachate containment.

Which of the two is better? it depends. For small scale use in the garden it may be vermicomposting for wet food waste, especially when fed every day. If yard waste is involved a decent size compost heap with regular turning (and a batch system where all material is composted the same time) will work. In cases where the compost is sold or given away to the public, quality standards must be met including those for sanitizing the compost in the hot process. A large commercial set-up is then required.

Worms And Vermicomposting: Best Types Of Worms For Vermicomposting

Vermicomposting [1] is a quick, efficient way to convert kitchen scraps into a rich soil amendment using earthworms. Vermicompost worms break down organic matter, such as kitchen scraps [2], into waste products called castings [3]. Although castings may be waste to the worms, they are a rich treasure for gardeners. Vermicompost is richer in essential plant nutrients such as nitrogen [4], phosphorous [5] and potassium [6] than traditional compost [7]. It also contains microbes that help plants grow. [8]

Can Any Type of Earthworm be Used for Vermicomposting?

The best types of worms for vermicomposting are red wigglers (Eisenia fetida) and redworms (Lumbricus rubellus). These two species make great worms for the compost bin [9] because they prefer a compost environment to plain soil, and they are very easy to keep. Worms that feed on vegetable waste, compost, and organic bedding produce richer casting than those that feed on plain soil.

You won’t find red wigglers in garden soil. You may find redworms near compost, under rotting logs, and in other organic situations. The problem is identifying them. You won’t be able to tell the difference between Lumbricus rubellus and other worms, so it’s best to buy them. If you don’t have a local supplier, you can order them on the Internet. It takes one pound of worms (1,000 individuals) to start a good-sized compost bin.

Worms and vermicomposting bins don’t smell, so you can keep worms indoors year round [10]. It’s a great way to use up your kitchen scraps and the kids will enjoy helping out with the worm farm. If you choose the right vermicomposting worm types and feed them regularly [11] (about one-half pound of food scraps per pound of worms per day), you’ll have a steady supply of vermicompost for your garden.

Drawbacks

Vermicomposting, or worm farming, has been a part of organic and natural gardening methods for years. Vermicomposting has both supporters and detractors; like any gardening method, it also has many advantages and disadvantages. Learn about some of the disadvantages before going into this method of composting.

You won’t find red wigglers in garden soil. You may find redworms near compost, under rotting logs, and in other organic situations. The problem is identifying them. You won’t be able to tell the difference between Lumbricus rubellus and other worms, so it’s best to buy them. If you don’t have a local supplier, you can order them on the Internet. It takes one pound of worms (1,000 individuals) to start a good-sized compost bin.

Worms and vermicomposting bins don’t smell, so you can keep worms indoors year round [10]. It’s a great way to use up your kitchen scraps and the kids will enjoy helping out with the worm farm. If you choose the right vermicomposting worm types and feed them regularly [11] (about one-half pound of food scraps per pound of worms per day), you’ll have a steady supply of vermicompost for your garden.

Drawbacks

Vermicomposting, or worm farming, has been a part of organic and natural gardening methods for years. Vermicomposting has both supporters and detractors; like any gardening method, it also has many advantages and disadvantages. Learn about some of the disadvantages before going into this method of composting.

Ratios Between Waste and Time

Vermicomposting requires waste to be applied in thin layers because of temperature concerns. If you apply too much waste to the bin in a short amount of time, the temperature will rise too fast and kill off the worms. Large quantities of waste must be spread out over large areas of ground to maintain the correct temperature.

Vermicomposting requires waste to be applied in thin layers because of temperature concerns. If you apply too much waste to the bin in a short amount of time, the temperature will rise too fast and kill off the worms. Large quantities of waste must be spread out over large areas of ground to maintain the correct temperature.

Temperature Limits

Vermicomposting requires a low temperature to be maintained in the compost operation so the worms do not lose moisture and dry out. The normal temperature for vermicomposting is between 55 and 80 degrees F.

Vermicomposting requires a low temperature to be maintained in the compost operation so the worms do not lose moisture and dry out. The normal temperature for vermicomposting is between 55 and 80 degrees F.

Care

Vermicomposting requires greater care than regular composting methods. The worms used in vermicomposting require care, food, heat and moisture at proper levels to remain healthy and create the compost material.

Vermicomposting requires greater care than regular composting methods. The worms used in vermicomposting require care, food, heat and moisture at proper levels to remain healthy and create the compost material.

Cost

Vermicomposting is more expensive to set up than regular compost piles or batch composters. Vermicomposting needs special materials to start, such as plastic or metal containers and red worms. Regular composting requires nothing but a hill or barrel to start. Vermicomposting also requires lime to stabilize the acid levels created by the waste in the new soil.

Vermicomposting is more expensive to set up than regular compost piles or batch composters. Vermicomposting needs special materials to start, such as plastic or metal containers and red worms. Regular composting requires nothing but a hill or barrel to start. Vermicomposting also requires lime to stabilize the acid levels created by the waste in the new soil.

Size Scales

Vermicomposting requires more space than regular composting. Eventually, you will need several bins to get the same compost yield as you would from one traditional composting bin.

Vermicomposting requires more space than regular composting. Eventually, you will need several bins to get the same compost yield as you would from one traditional composting bin.

Concerns

Vermicomposting does not destroy any weed seeds which may have entered the bedding area with the food supply. There is not enough evidence to show that pathogens would be destroyed if large amounts of pathogens are present in organic material. Bedding must be provided that allows the worms to breed away from their food.

Composting is the speeding up of the natural process of decomposition. The goal is to improve soil composition by returning useful waste back to your garden

One of the most significant contributors for composting is kitchen waste. Scraps from meal preparations as well as cooking supplies can be added to a compost bin and, in turn, contribute to your soil and mulch. Vermicomposting is a compliment to the process by increasing the value of nutrients returned to the soil.

Vermicomposting instead of composting gives gardeners five key benefits.

Vermicomposting does not destroy any weed seeds which may have entered the bedding area with the food supply. There is not enough evidence to show that pathogens would be destroyed if large amounts of pathogens are present in organic material. Bedding must be provided that allows the worms to breed away from their food.

Composting is the speeding up of the natural process of decomposition. The goal is to improve soil composition by returning useful waste back to your garden

One of the most significant contributors for composting is kitchen waste. Scraps from meal preparations as well as cooking supplies can be added to a compost bin and, in turn, contribute to your soil and mulch. Vermicomposting is a compliment to the process by increasing the value of nutrients returned to the soil.

Vermicomposting instead of composting gives gardeners five key benefits.

1. Diverting waste from landfills is excellent, and vermicomposting also produces nutrient-rich castings for your garden.

2. Compared to traditional composting less space is needed.

A bin with a couple square feet of surface area 8 -16 inches deep works well. So do five-gallon buckets buried in the ground.

A bin with a couple square feet of surface area 8 -16 inches deep works well. So do five-gallon buckets buried in the ground.

A bin with a couple square feet of surface area 8 -16 inches deep works well. So do five-gallon buckets buried in the ground.

A bin with a couple square feet of surface area 8 -16 inches deep works well. So do five-gallon buckets buried in the ground.3. Less strength is needed.

The worms do the work, so you don’t have to measure temperature and turn the pile.

The worms do the work, so you don’t have to measure temperature and turn the pile.

4. Faster production of compost.

This depends on the temperature of your compost pile, but 3 months to a year is a typical time period for a compost pile to be ready. Vermicomposting should be ready around every three months.

This depends on the temperature of your compost pile, but 3 months to a year is a typical time period for a compost pile to be ready. Vermicomposting should be ready around every three months.

5. Red wiggler worms eat half their weight in food waste daily.

Imagine if a 200-pound man could eat 100 pounds of garbage every day?

Vermicomposting has some challenges as well. You need to make sure you don’t let your worm beds dry out or keep them to wet. Worms like fruit, vegetables, coffee grounds, and pasta. Don’t feed them meat scraps because it will smell and attract unwanted pests. You should harvest about every three months. Your mileage will vary depending on temperatures, moisture and how much you feed your worms. Soil makes one of the most significant differences in how your landscape looks and how much food your garden produces. Vermicomposting won’t solve all the problems in your garden, but it will give you the opportunity to reduce waste while improving the look and production of your garden.

Vermicomposting has some challenges as well. You need to make sure you don’t let your worm beds dry out or keep them to wet. Worms like fruit, vegetables, coffee grounds, and pasta. Don’t feed them meat scraps because it will smell and attract unwanted pests. You should harvest about every three months. Your mileage will vary depending on temperatures, moisture and how much you feed your worms. Soil makes one of the most significant differences in how your landscape looks and how much food your garden produces. Vermicomposting won’t solve all the problems in your garden, but it will give you the opportunity to reduce waste while improving the look and production of your garden.

Imagine if a 200-pound man could eat 100 pounds of garbage every day?

Vermicomposting has some challenges as well. You need to make sure you don’t let your worm beds dry out or keep them to wet. Worms like fruit, vegetables, coffee grounds, and pasta. Don’t feed them meat scraps because it will smell and attract unwanted pests. You should harvest about every three months. Your mileage will vary depending on temperatures, moisture and how much you feed your worms. Soil makes one of the most significant differences in how your landscape looks and how much food your garden produces. Vermicomposting won’t solve all the problems in your garden, but it will give you the opportunity to reduce waste while improving the look and production of your garden.

Vermicomposting and Worm Farming

Vermicomposting – Composting with the Worms

Vermis is the ancient Latin word for “worms”, so Vermicomposting is essentially the decomposition of organic material by worms. In other words, “Worm Composting”. The worms perform their magic on both waste matter and the soil producing a nutrient-rich, organic fertiliser and soil conditioner, called “vermicompost”.

Generally a traditional aerobic compost heap gets too hot in its centre for anything to live there other than bacterial organisms. But in cooler compost heaps, a lot of the work of decomposition can be done by worms and a composting process that relies entirely on worms is called “vermicomposting”.

Vermicomposting is an easy but fairly slow way of turning vegetable and food scraps as well as garden waste into high-quality compost and soil conditioner for use by the gardener. Another advantage of using worms, is that worms are abundant (20 to 50 per square foot), odourless, free from disease and work all year-round given the right conditions. Then, vermicomposting results in the bio-conversion of the waste stream into two useful products, “earthworm biomass” and “vermicompost”.

Vermis is the ancient Latin word for “worms”, so Vermicomposting is essentially the decomposition of organic material by worms. In other words, “Worm Composting”. The worms perform their magic on both waste matter and the soil producing a nutrient-rich, organic fertiliser and soil conditioner, called “vermicompost”.

Generally a traditional aerobic compost heap gets too hot in its centre for anything to live there other than bacterial organisms. But in cooler compost heaps, a lot of the work of decomposition can be done by worms and a composting process that relies entirely on worms is called “vermicomposting”.

Vermicomposting is an easy but fairly slow way of turning vegetable and food scraps as well as garden waste into high-quality compost and soil conditioner for use by the gardener. Another advantage of using worms, is that worms are abundant (20 to 50 per square foot), odourless, free from disease and work all year-round given the right conditions. Then, vermicomposting results in the bio-conversion of the waste stream into two useful products, “earthworm biomass” and “vermicompost”.

Vermicompost Redworms